Our factory have three categories of refractory materials: Acid, Basic & Neutral. Apart from these we can classify refractories into few more categories like – Special refractories, Insulating Refractories, & Cermets.

Refractory materials are non-metallic materials with refractoriness not less than 1580℃. Widely used in metallurgy, chemical industry, petroleum, machinery manufacturing, power and other industrial fields, the largest amount in the metallurgical industry, accounting for 50% -60% of the total output. Now for the definition of refractory materials, not only depends on whether the refractoriness is above 1580 ℃; but also refers to inorganic non-metallic materials used in metallurgy, petrochemical, cement, ceramics and other production equipment lining. Read this article to learn more about the classification and function of refractory materials.

Refractory materials are classified as neutral, basic or acidic. Whether it is refractory bricks or refractory castables are also distinguished by these three properties.

Refractory materials have a variety of classification methods

According to the chemical nature of the classification, can be divided into acid refractory materials, alkaline refractory materials and neutral refractory materials.

Neutral refractories are made of alumina or carbon. There are high alumina, corundum, carbon refractory bricks and castables.

Acid is to silicon oxide as a component of refractory materials, products have silicon and clay refractory bricks and castables, such as silicon bricks, lightweight silicon bricks, acid-resistant bricks, clay bricks, acidic castables, acidic lightweight castables, acid products are mainly used for coke ovens, glass melting kilns and other kiln linings. Clay bricks are weakly acidic, but have good thermal shock and are most widely used.

Alkaline is magnesium oxide, calcium oxide as the main component of refractories, products include magnesium bricks, straight magnesium bricks, magnesium-aluminum spinel bricks and containing magnesium oxide more than 80 to 85 irregular castables, alkaline materials on slag and iron resistance, refractoriness acidic than neutral products, alkaline products are mainly used for alkaline atmosphere of the kiln lining, such as rotary kiln, converter and so on. Alkaline refractories in the magnesium dolomite refractory bricks are strongly alkaline, chrome magnesium and magnesium olivine refractory bricks or castables and spinel composite class belongs to the category of weakly alkaline refractories.

Neutral, alkaline, acidic is mainly based on the main components in the body to distinguish between acidic refractories contain a certain amount of silica acidic refractories are silica bricks and silica castables, 94-97% of the silicon (SiO2) composition. Clay refractories are weakly acidic compared to siliceous with less silicon content (SiO2). Semi-siliceous materials also border on their intermediacy.

Neutral materials in the high-alumina brick, corundum brick, high-alumina castables, corundum castables, mullite castables, is higher than 45% of the aluminum content tends to neutral materials, chrome refractories are also alkaline and tends to neutral refractories.

Refractory materials in all raw materials are basically natural minerals, are based on the grade of raw materials and processed into different grades of refractory bricks or castables, so no matter what the nature of the different quality points.

Classification of refractory materials

Depending on the operating environment, they must be resistant to thermal shock, be chemically inert, have specific ranges of thermal conductivity and of the coefficient of thermal expansion.

1.Acidic refractoriesconsist of acidic materials like alumina (Al2O3), and silica (SiO2). They are impervious to acidic materials, but easily attacked by basic materials. Important members of this group are alumina, silica, and fireclay refractories.

2.Basic refractoriesconsist of basic materials such as CaO, MgO, etc. These are impervious to basic materials, but easily attacked by acidic materials. Important members of this group are magnesite and dolomite refractories.

3.Neutral refractories are made from weakly acid/basic materials such as carbon, silicon carbide (SiC), chromite (FeCr2O4) and zirconia (ZrO2).

What are the common refractory materials?

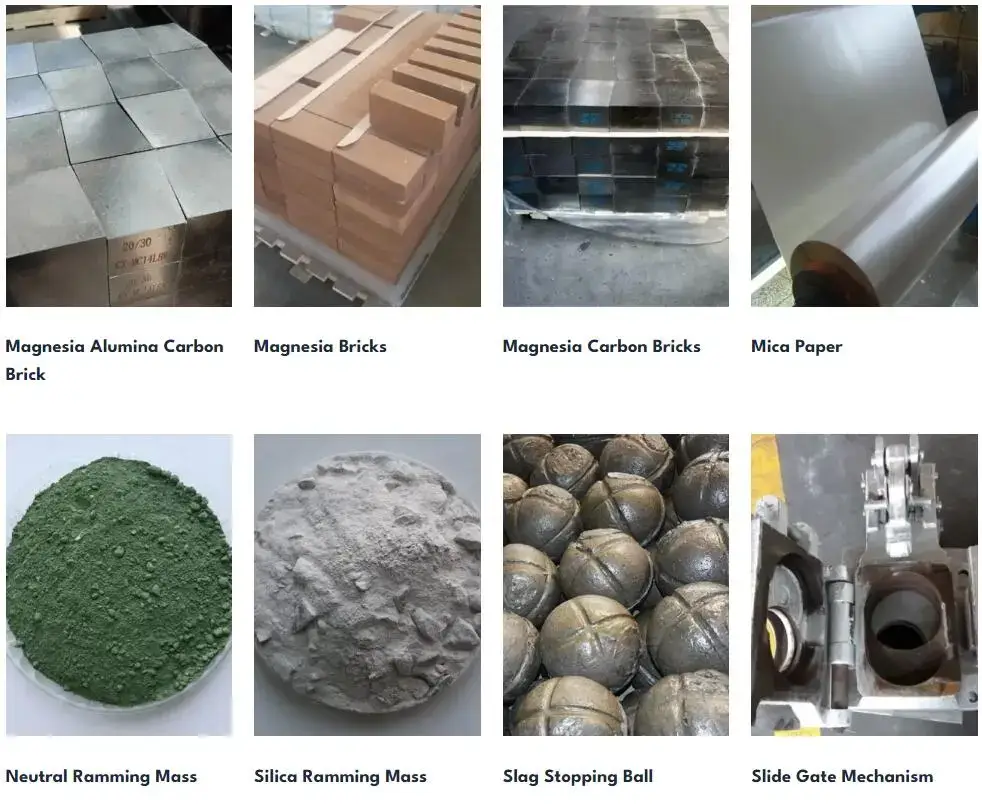

Frequently used ordinary refractory materials are silicon bricks, semi-silicon bricks, clay bricks, high alumina bricks, magnesium bricks and so on.

Frequently used special materials are AZS bricks, corundum bricks, direct bonded magnesium-chromium bricks, silicon carbide bricks, silicon nitride bonded silicon carbide bricks, nitrides, silicides, sulfides, borides, carbides, and other non-oxidizing refractories; calcium oxide, chromium oxide, alumina, magnesium oxide, beryllium oxide and other refractory materials.

Heat-insulating refractories are diatomite products, asbestos products, adiabatic panels and so on.

Unshaped refractory materials such as furnace materials, refractory pounding materials, refractory castables, refractory plastic, refractory mud, refractory spraying materials, refractory projectiles, refractory coatings, lightweight refractory castables, clay, ceramic valves and so on.

What are the physical properties of refractory materials?

The physical properties of refractory materials include structural properties, thermal properties, mechanical properties, utilization properties and operational properties.

The structural properties of refractory materials include porosity, bulk density, water absorption, permeability, pore size distribution and so on.

Thermal properties of refractory materials include thermal conductivity, coefficient of thermal expansion, specific heat, heat capacity, thermal conductivity, thermal emissivity and so on.

Mechanical properties of refractory materials include compressive strength, tensile strength, flexural strength, torsional strength, shear strength, impact strength, abrasion resistance, creep, bond strength, modulus of elasticity and so on.

The operational properties of refractory materials include refractoriness, load softening temperature, reburning line change, thermal shock resistance, slag resistance, acid resistance, alkaline resistance, hydration resistance, CO erosion resistance, electrical conductivity, oxidation resistance and so on.

The workability of refractory materials includes consistency, collapse, flow, plasticity, adhesion, resilience, coagulability, hardenability, and so on.

Continuous economic development and increasing industrialization level have gradually upgraded the consumption demand and structure of refractories. With the advancement of supply-side structural reform, the supply-side structure and demand-side changes are upgraded synchronously, and the market space of refractories has been transformed from high-speed growth in the past to a stable transition state.

The total consumption of refractories tends to decline, and the pattern of downstream consumption will be adjusted. Based on the promotion of capacity dissolution in iron and steel, building materials and other industries, the proportion of refractories consumption will be reduced. At the same time, there is a huge space for refractory material variety structure adjustment, service mode will be transformed, and industrial layout will be adjusted accordingly.