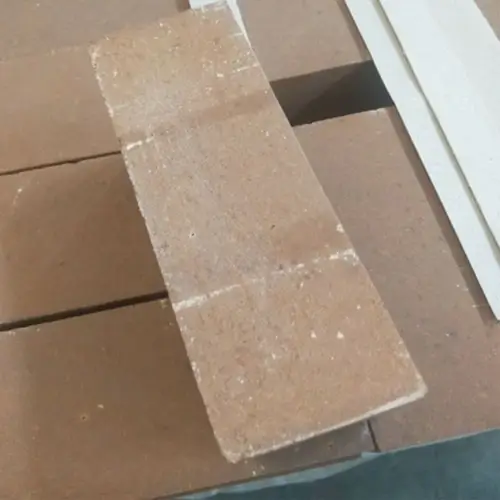

What is Magnesia Brick?

Magnesia Bricks are alkaline refractory materials. These products have high percentage of magnesium oxide content and adopt periclase as the principal crystalline phase. Magnesia Bricks can be divided into two categories of Burnt Magnesia Bricks and Chemical Bonded Magnesia Brick. They have excellent performance of superior high temperature mechanical strength and volume stability. Magnesia Bricks can service in the high temperature of 1750℃. They are ideal products for glass furnace application.

What is Magnesia Bricks Manufacturing Process?

Burnt Magnesia Bricks are manufactured with magnesite clinker as the raw material and fired in the high temperature of 1550~1600℃ after smashing, burdening, mulling and molding. High-purity products can be fired in the temperature that over 1750℃. Chemical bonded magnesite brick is produced with certain chemical bonding through mixing, molding and drying.

The regular magnesia bricks are made from dense dead burned magnesia that makes the bricks in good refractoriness, corrosion-resistance, and widely used in checker chamber of glass tank, lime kiln, non-ferrous metallurgical furnaces, open heart furnace, iron mixer and EAF of steel-making, and also ferro-alloy furnace, etc. The bricks with MGO 95% or more in content take the secondary-burning dead burned magnesia or electrofused magnesia as the raw material and bured under the condition of ultra high temperature. They have the features of highly directly bonded and corrosion-resistance and widely used in various kinds of high temperature kilns and furnaces.

What’s the Application of Magnesia Bricks?

Basic open-hearth furnace for steelmaking

Electric furnace bottom and wall

Permanent lining of oxygen converter

Non-ferrous metal metallurgy furnace

Hyperthermia tunnel kiln

Lining of rotary cement kiln

Heating furnace bottom and wall

Regenerative chamber of glass furnace

The most important steps need to be considered to avoid or reduce the possibility of magnesia bricks hydration are:

1. Magnesia bricks must be transported in a container to protect the material against moisture.

2. Magnesia bricks should be stored inside storage rooms where it is dry, free of frost, ventilated, and with a temperature between 10°C and 30°C (see figure- 23). Note that magnesia bricks storage underneath a tarpaulin cover outside is not sufficient.

3. Bricks may not be stored for more than four weeks prior to installation and preheating.

4. Lining should be protected against moisture during installation and preheating.

Reviews

There are no reviews yet.