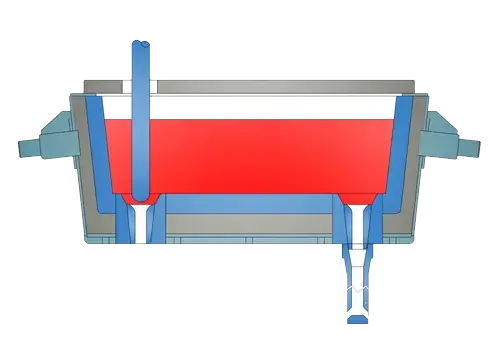

The tundish is a refractory container that first receives the molten steel poured from the ladle and then distributes it to each crystallizer through the tundish water outlet. Its functions are:

(1) Reduce the static pressure of the molten steel, maintain a stable molten steel level in the tundish, and inject the molten steel into the crystallizer in a balanced manner;

(2) Promote the further floating of inclusions in the molten steel to purify the molten steel;

(3) Divert the molten steel. For multi-strand continuous casting machines, the molten steel is distributed to each crystallizer through the tundish:

(4) Store the molten steel. When changing the ladle during multi-furnace continuous casting, the casting speed is not reduced, creating conditions for multi-furnace continuous casting.

The tundish’s primary functions are to reduce pressure, stabilize the flow, remove inclusions, and store and divert molten steel.

What does “tundish metallurgy” mean?

With increasing demands for steel quality, various ladle refining technologies have been developed to improve purity and make the molten steel “cleaner.” The tundish is a refractory container between the continuous casting ladle and the crystallizer. Molten steel can be considered “clean” after external refining, but it can be re-contaminated when poured into the tundish. Therefore, the tundish should not be viewed as a simple steel transfer container, but rather as a continuous metallurgical reactor. The methods used in ladle refining can be transferred to the tundish to further purify the molten steel. For this reason, the concept of tundish metallurgy has been proposed and has gained considerable attention.

The functions of tundish metallurgy are:

(1) Purification function

In order to produce high-purity steel, measures such as retaining walls and dams, argon blowing, and ceramic filters are used in the tundish to significantly reduce the content of non-metallic inclusions in the steel, and significant results have been achieved in production.

(2) Temperature control function

In order to make the temperature difference of the molten steel in the front, middle, and late stages of the tundish less than 5°C during the pouring process, pour close to the liquidus temperature, expand the equiaxed crystal zone of the ingot, and reduce central segregation, measures such as adding small pieces of scrap steel to the tundish and spraying iron powder can be taken to adjust the molten steel temperature.

(3) Composition fine-tuning

Aluminum, titanium, boron, etc. are fed into the crystallizer through the center hole of the tundish plug rod to achieve fine-tuning of the micro-alloy composition in the steel, which not only improves the recovery rate of easily oxidized elements, but also avoids nozzle blockage.

(4) Refining function.

Adding double-layer slag to the surface of the molten steel in the tundish to absorb the floating inclusions in the steel, or feeding calcium wire in the tundish to change the shape of AI2O3 inclusions and prevent nozzle blockage.

(5) Heating function.

Induction heating and plasma heating are used in the tundish to accurately control the pouring temperature of molten steel within ±3 to ±5°C.

What is the definition and significance of the residence time of molten steel in the tundish?

The time the molten steel spends in the tundish from the time it enters the ladle to the time it flows into the mold is called residence time.

It is defined as: t = v / Q

t—residence time of the molten steel in the tundish, min;

V—volume or weight of the molten steel in the tundish, m³ or t;

Q—flow rate of the molten steel in the tundish, t/min.

For example, if the molten steel in the tundish weighs 18 tons, the billet being cast is 150×150 mm², and the casting speed v is

2.6 m/min, then the flow rate Q is:

Q = 0.15 × 0.15 × 2.6 × 7.0 × 4 = 1.638 t/min

So, t = 18/1.638 ≈ 11 minutes

In other words, the molten steel’s residence time in the tundish is 11 minutes. If the molten steel flows too quickly from the nozzle to the mold within the tundish, inclusions won’t have time to float up.

The general principle is: the longer the molten steel resides in the tundish, the more time inclusions have to float up, and the cleaner the molten steel. To increase the molten steel’s residence time, an effective method is to use a tundish with a large capacity and a deep melt pool.

What is the purpose of adding retaining walls and dams to the tundish?

The theoretical residence time is calculated from the tundish capacity and the amount of molten steel in the tundish. However, in actual production, the flow of molten steel in the tundish is uneven, with some areas flowing faster and others slower. In particular, there is an inactive stagnant zone at the bottom of the tundish, making it difficult for inclusions to float up. The actual average residence time of molten steel in the tundish is shorter than the theoretical average residence time. To effectively utilize the tundish volume and promote the floating of inclusions, retaining walls and dams are added to the tundish. Their purpose is:

—Eliminate the dead zone at the bottom of the tundish.

Improves the molten steel flow trajectory, directing it along the steel-slag interface, shortening the distance inclusions float, and facilitating slag absorption.

The retaining wall also confines the intense eddies caused by the ladle’s impact, preventing the spread of turbulent flow and surface fluctuations that could draw slag into the molten steel.

The location and size of retaining walls and dams should be determined through water model testing based on the actual tundish, and then implemented in production. The use of retaining walls in the 10t tundishes of the 3# and 4# continuous casting machines at a certain steel plant reduced inclusions in the tundish steel by approximately 30%, and inclusions in the slab by 30-40%, while other process conditions remained unchanged. Other tests have shown that the use of retaining walls and dams in the tundish improves steel cleanliness. Without retaining walls, the surface aluminate inclusions in the slab were 2.9%, while with retaining walls, the inclusions were 2.1%. With retaining walls and dams, the surface inclusions were reduced from 2.1% to 0.3%.

What is the critical liquid level of molten steel in the tundish?

As we know from practical experience, when a container is filled with water and the water flows out of the bottom hole, when the liquid level drops to a certain height, a vortex is generated above the outlet hole. This phenomenon also occurs in the tundish.

There are two critical heights:

One is the height at which the tundish must be filled before pouring begins;

the other is the height at which the molten steel level must drop to at the end of the pouring process before pouring is stopped.

Both methods have a critical height. If the molten steel level falls below this critical height, vortices form on the molten steel surface, drawing slag into the mold, increasing inclusions in the steel and potentially rendering the product scrapped.

If pouring is stopped at a critical height, residual steel will be lost in the tundish, reducing the yield.

For example, if a 40t tundish is used for four continuous pours, 10t of molten steel will remain, resulting in a 0.86% yield loss; if 12.5t of molten steel remains, the yield loss is 1.08%. Increasing the number of continuous pours to achieve the lowest molten steel level, achieving the optimal yield while avoiding slag entrainment and producing good ingot quality, is the optimal approach.

The trade-off between steel yield loss and ingot quality is primarily determined by product quality. If inclusion requirements are stringent, some steel loss is preferable. If quality requirements are less stringent, the critical liquid level height can be less critical.

The critical liquid level height can be determined through observations in water model tests. Depending on the tundish capacity, the critical height at which the steel level drops is generally 200-300 mm.

What are the characteristics of tundish steel flow?

Flow velocity, flow trajectory, and turbulence intensity are generally used to describe fluid flow characteristics.

Tundish flow characteristics:

(1) The ladle flow acts like a “jet pump”, drawing the surrounding air into the tundish steel liquid and breaking it into small bubbles, forming additional circulation, aggravating the secondary oxidation of the molten steel.

(2) The impact zone of the ladle flow into the tundish is a highly turbulent area, which is prone to slag entrainment.

(3) Vortex formation. At the end of pouring, when the tundish liquid level drops to a critical height, a vortex is formed above the nozzle, entraining slag into the crystallizer. At the same time, the tundish flow is unstable, stirring the flow of molten steel in the crystallizer.

(4) Surface wave formation. When the tundish steel liquid level is unstable during pouring, ladle replacement, and at the end of pouring, surface waves are easily generated, causing slag to be entrained into the molten steel.

Therefore, the unstable state caused by the flow of molten steel in the tundish will aggravate secondary oxidation and cause slag to be drawn into the molten steel, seriously affecting the cleanliness of the steel. Therefore, efforts should be made to reduce the harm caused by the flow by adopting the following measures:

(1) Use a tundish with a large capacity and a deep molten pool.

(2) Use a long nozzle from the ladle to the tundish, which can not only protect the steel flow from secondary oxidation, but also reduce the turbulence in the impact zone of the steel flow and prevent slag entrainment.

(3) Set up retaining walls and dams to control the flow trajectory and prevent the spread of turbulence in the impact zone.

(4) When changing the ladle during continuous casting, efforts should be made to prevent the liquid level from fluctuating too much.

How do open pouring and long-nozzle pouring affect molten steel flow in the tundish?

When the tundish maintains a normal liquid level and ladle pouring is performed using open pouring, the characteristics of molten steel flow in the tundish are:

1) Turbulence in the injection impact zone causes wave motion on the molten steel surface, which can easily lead to slag entanglement.

2) Shear forces act along the steel-slag interface, entraining slag inside.

3) Shear forces at the steel-slag interface are reduced.

4) Turbulence and wave motion caused by injection are reduced.

If a retaining wall and dam are used in conjunction with the tundish, slag entanglement can be significantly reduced.

Regardless of the tundish structure, the flow patterns that cause slag entanglement are: turbulence in the injection impact zone, surface waves at the steel-slag interface, and vortex flow. Therefore, effective measures to prevent slag entanglement include long shrouds, deep melt pools, and retaining walls and dams.

What is the function of the tundish covering agent?

The functions of the tundish covering agent are:

1) Insulate and prevent heat loss;

2) Absorb rising inclusions (such as Al₂O₃ and calcium aluminates);

3) Isolate air, preventing oxygen from entering the molten steel and preventing secondary oxidation.

However, for steel grades with stringent quality requirements, the content of non-metallic inclusions, particularly Al₂O₃, must be reduced to prevent defects such as cracks and black lines in the product. To this end, the tundish lining is made of alkaline refractory materials (magnesia insulation boards or magnesia coatings), and the tundish utilizes a double-layer covering slag. Molten mold slag on the molten steel surface absorbs inclusions such as Al₂O₃, while rice husk ash provides insulation and heat preservation.

The composition of the tundish mold slag differs from that of the mold slag. Because the tundish lining is alkaline, the mold slag must have a high alkalinity and good inclusion absorption capacity to prevent rapid lining erosion.