In view of the causes of various cracks, from the process, operation and other aspects of the introduction of measures to limit and reduce cracks, in order to achieve the best performance of the use of ladle slide gate.

1.Improve the thermal shock resistance of the slide gate material

By reducing the coefficient of thermal expansion and modulus of elasticity of the slide gate material and improving the resistance to thermal shock, the damage to the slide gate caused by thermal stress can be effectively mitigated, and the danger of cracking can also be reduced.

2.Optimization of the shape of the slide plate and the top tightening method

Optimization of the shape of the slide plate and the top tightening method, especially the use of finite element method. Such as increasing the width of both sides of the casting hole, reduce the width of other parts of the water drop-shaped linear arc connection, so that the full use of high-quality refractory materials, is conducive to reducing the concentration of thermal stress. For the longitudinal cracks produced by the slide due to coordination with the mechanism, the fundamental solution is to improve the coordination between the slide and the mechanism, such as by the point of contact changed to line contact, from line contact changed to surface contact, etc. It can greatly reduce the generation of such cracks.

3.Optimize the flatness of the mechanism

When found due to the sliding gate mechanism is not flat cracks, the need to test the flatness of the mechanism, if the slide plate and the mechanism is rigid contact, can consider adding buffer in the bonding surface, such as ceramic pads to alleviate. In the field operation need to pay attention to the use of compressed air to carefully blow the slide plate groove, assembly surface, sliding trolley, frame and mechanism of the base and other parts, and in the installation of the slide gate plate with a hand gently press the slide gate plate, to see whether there is a wobble, the use of these ways to determine the coordination of the slide gate plate and the mechanism to confirm that the coordination of the slide gate plate and the mechanism of the smoothness of the fit.

4.Adjust the material of the slide gate plate

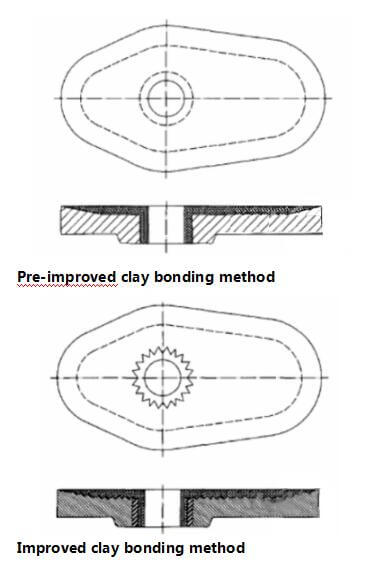

For the cracks caused by the different materials of the slide gate plate, the cracks can be minimized by adjusting the way of combining the clay materials and other measures.For example, you can use a special feeding cylinder in the mud combination part to make two kinds of mud staggered combination, increase the interface area and bonding force, as shown in Figure 1. Special attention should also be paid to the matching of the thermal expansion of the two materials.

5.Improvement of cracks on slide gate and sub-master ports

For the cracks produced on the surface of the sliding gate plate and at the sub-mother mouth, improvement can be made in the following aspects. On the one hand, cracks can be minimized by improving the fluidity of the clay during the pressing process, such as adjusting the slope of the edge of the mother and father ports. On the other hand, cracks can be minimized by calculating the density of the clay and using a tool to make the difference in density between the mother tongue and the surface of the pressed slide smaller. In addition, the strength of the mold can be considered to reduce cracks.

6.The tightness of lower nozzle

In the hot repair of the cracks generated by the tightening of ladle lower nozzle, can be carried out by changing the operating habits. Under the mouth of the tightening is not the tighter the better, but to be just right, due to the slide and the mouth of the middle of the 1 ~ 2mm of fire clay, in the process of tightening the under the mouth of the spinning sleeve, do not make full force, when the hammer falls to the spinning sleeve when there is a bit of rebound to prove that the under the mouth of the spinning has been tightened, this point of the hot repair of the site of the actual operation of the experience requirements are high.Under the mouth of the tightening is not the tighter the better, but to be just right, due to the slide and the mouth of the middle of the 1 ~ 2mm amount of fire clay, in the process of tightening the under the mouth of the spinning sleeve, do not make full force.

When the hammer falls on the spinning sleeve has a little rebound when the proof of the lower nozzle has been tightened, this point on the hot repair site of the actual operation of the higher experience requirements.