Current status and problems faced by cord steel

Cord steel is made from specialized high-carbon steel wire rods, drawn multiple times to form fine steel wires with unit diameters ranging from 0.15 to 0.38 mm. These wires are then twisted into strands to form a steel wire product. Tires with a metal mesh made of cord steel as a skeleton, interlaced and layered within the tire colloid to support the carcass, are commonly referred to as “steel radial tires.” Radial tires possess exceptional elasticity and strength, capable of withstanding the immense pressures experienced by vehicles during extended high-speed driving. They also offer excellent wear resistance and heat stability, ensuring safety and comfort.

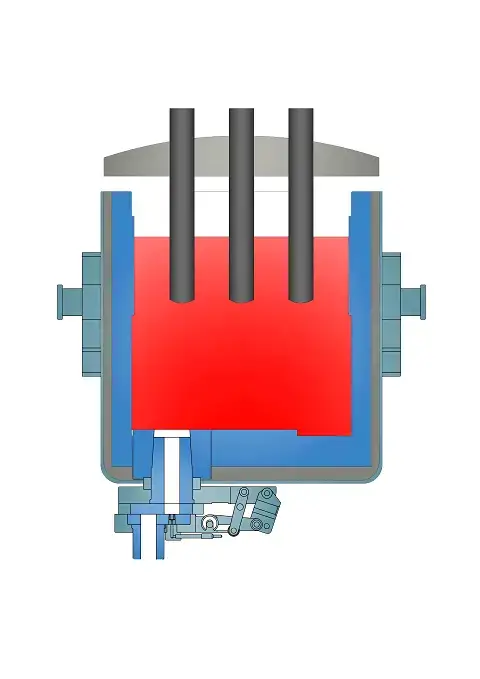

The most common problem in cord steel production is breakage during deep drawing or coiling. Analysis of the inclusions found on the fractured surfaces of broken wires revealed that the primary cause of breakage is hard Al2O3 inclusions, primarily from crystallization in molten steel and introduction into refractory materials. Oxide inclusions primarily refer to Al2O3, SiO2, TiO2, MgO, and their complex oxides. Among these, Al2O3 is the most common and most harmful, often becoming the source of stress concentration in cord steel. The larger the Al2O3 inclusion, the greater its impact on fatigue life, and polygonal inclusions have a greater impact on fatigue life than spherical inclusions. Cord steel smelting requires strict control of inclusions and segregation in the steel. The presence of larger inclusions, especially brittle inclusions such as Al2O3 and calcium aluminates with poor deformability, is the main cause of wire breakage. Therefore, targeted design and selection of suitable ladle lining materials should be used in cord steel smelting to avoid wire breakage during steel processing and thus improve steel quality.

Research progress of refractory materials for ladle

Ladle refractories have continuously evolved and improved with the development of steelmaking technology and processes, as well as the exploration and utilization of refractory resources. There are roughly 10 different materials used for ladle lining refractory materials. Due to differences in smelting technology and raw material supply in different countries at the time, the materials used for ladle linings also varied during the same period. However, they can generally be divided into three stages: the aluminosilicate brick stage, the high-alumina brick and alkaline/neutral brick lining stage, and the monolithic ladle lining stage. Furthermore, they can be further divided into the shaped refractory product stage and the monolithic refractory product stage.

Shaped Refractory Product Stage

Magnesia refractories are widely used in the steel and metallurgical industry due to their strong resistance to slag erosion and their lack of contamination of molten steel. However, their resistance to slag penetration and thermal shock is relatively poor. Carbon composite refractories have achieved satisfactory results in producing high-performance refractories that combine slag erosion resistance and thermal shock resistance. However, the carbon in carbon-containing refractories is easily oxidized, weakening its advantages and leading to material damage. Furthermore, the addition of carbon contaminates the molten steel, hindering the production of clean steel. MgO-C refractory materials, a material that emerged in the 1970s, are unburned refractory materials made from high-temperature sintered or fused magnesia and carbon as the primary raw materials, with a carbon binder. The materials are then formulated, mixed, formed, and heat-treated. MgO-C refractory materials were first developed in 1970 by Akira Watanabe and others at Kyushu Refractories Co., Ltd. in Japan. Experiments with hotspots in high-power and ultra-high-power electric furnaces and the gas inlets of bottom-blown converters increased the lining life of ultra-high-power electric furnaces from 2-3 days compared to traditional basic bricks to 2-3 weeks, significantly increasing electric furnace steelmaking productivity and leading to widespread adoption. In 1977, Kawasaki Steel Corporation in Japan introduced the Q-POB converter, which used resin-bonded MgO-C bricks for the converter bottom and tuyere, achieving great success. Between 1978 and 1979, Japanese researchers published numerous research reports on MgO-C refractory materials. Since 1979, Japan has been using MgO-C bricks in various parts of converters. Compared to previously tar-impregnated and fired magnesia dolomite bricks, converter life has increased by 13 to 16 times. Compared to tar- or pitch-bonded bricks, such as ingot plugs, continuous casting slides, nozzle bricks, submerged nozzles, and dolomite bricks used in the early stages of converter steelmaking, MgO-C bricks leverage the slag-resistant properties of natural flake graphite, including high thermal conductivity and a low coefficient of thermal expansion. These bricks significantly improve the spalling and slag-erosion resistance of basic refractories. MgO-C bricks are unfired products, saving approximately 80% of energy compared to fired bricks. Therefore, this type of refractory material can be considered a groundbreaking refractory. He Pingxian et al. used induction furnace experiments to analyze the effects of three different carbon-content MgO-C bricks used in the ladle slag line (8.3%, 15.5%, and 17.9% carbon mass fractions, respectively), wax stone silicon carbide bricks used in the ladle bottom (3.71% carbon mass fraction), and a laboratory-developed MgO-Al2O3-SiC ladle slag line castable (4.07% carbon mass fraction) on the recarburization of IF steel. They also conducted a preliminary analysis and discussion of the recarburization mechanism. The experimental results showed that the higher the carbon content of the MgO-C bricks in the slag line, the greater the recarburization of IF steel. The wax stone silicon carbide bricks in the ladle bottom recarburized IF steel 7.73 times more than the MgO-C bricks in the slag line. The MgO-Al2O3-SiC castable also significantly recarburized IF steel and is not suitable for use as a ladle slag line material for smelting ultra-low carbon steel. my country began researching MgO-C bricks in 1976, and after 1986, they were widely adopted by major steel companies nationwide, rapidly increasing the service life of converter linings at many Chinese companies. Large steel companies such as Baosteel and Wuhan Iron and Steel have achieved converter service lives exceeding 10,000 converters through slag splashing technology. The practical application of MgO-C bricks in furnace linings has proven that they reduce refractory consumption, improve various technical specifications of the lining, and have positively promoted the development of the metallurgical industry.

Al2O3-MgO-C refractory materials are a new type of refractory material that began development in my country in the late 1980s and gained widespread application in continuous casting, electric furnaces, and refining ladles in the 1990s. The primary raw materials for Al2O3 in aluminum-magnesium-carbon bricks are fused white corundum, plate-shaped sintered corundum, sub-white corundum, brown corundum, and various grades of high-alumina bauxite clinker. The introduction of MgO into alumina-magnesia-carbon bricks is as follows: (1) adding it in the form of high-temperature sintered magnesia or fused magnesia fine powder; (2) adding it in the form of magnesium-rich spinel fine powder; (3) adding it in the form of a mixture of different particle types of magnesia and magnesia-alumina spinel. Al2O3-MgO-C refractory materials are mainly developed based on the performance characteristics of MgO-C and Al2O3-C refractory materials. Al2O3-MgO-C refractory materials have good chemical and thermodynamic stability and have higher thermal shock resistance and mechanical properties than MgO-C and Al2O3-C refractory materials. Al2O3-MgO-C refractory materials are currently mainly used for continuous casting, electric furnace and off-furnace refining ladle lining, ladle bottom and steel spout, etc. Al2O3-MgO-C refractory materials offer excellent resistance to erosion by molten steel and slag, good high-temperature resistance, resistance to structural spalling, and excellent residual expansion characteristics at high temperatures. Furthermore, due to their excellent thermal shock resistance, high refractoriness, and excellent slag and spalling resistance, they have long been used as ladle lining materials. However, the high thermal conductivity of Al2O3-MgO-C bricks not only causes a certain degree of temperature drop in the molten steel during the refining process but also often causes deformation of the cladding due to overheating. Furthermore, as a carbon-containing material, they tend to increase carbon in the molten steel during the production of low-carbon steel. Therefore, traditional Al2O3-MgO-C bricks are not suitable for the production of low-carbon and ultra-low-carbon steels.

Unshaped refractory products period

In recent years, refractory materials have been developing towards low consumption and low pollution. Castable refractories have seen rapid growth due to their simple production process, low cost, and excellent integrity. Japanese researchers developed magnesia-zircon refractory castables and explored their slag erosion resistance mechanism. They believe that zircon dissociates into zirconium oxide and SiO2 glass at high temperatures. The highly viscous SiO2 glass fills the matrix portion of the refractory structure, preventing early slag penetration. Hldeo Yaol et al. also studied magnesia-zircon refractory castables and proposed that the erosion mechanism of magnesia-zircon refractory castables is that after dissociation, zircon forms a softened film in the matrix, which inhibits slag penetration. However, this soft matrix film is susceptible to erosion, causing the sand to become loose. Improving the erosion resistance of the zircon matrix would also improve the erosion resistance of the magnesia-zircon refractory castable. Therefore, magnesia-zircon sand with a uniform zircon distribution should improve the erosion resistance of the castable.

For the purpose of refractory materials used in ladle refractories for cord steel smelting, domestic researchers selected three typical steel-containing Al2O3 refractory materials: alumina-magnesia castables, alumina-spinel castables, and Al2O3-MgO-C bricks. Induction furnace tests were conducted to analyze the aluminum content of the cord steel due to the Al2O3 in the refractory materials. The results showed that, without vacuum or wire treatment, none of the three Al2O3-containing refractory materials significantly increased the aluminum content of the cord steel.

A Japanese company used an alumina-magnesia spinel castable made by adding magnesium oxide to the alumina-spinel castable matrix, achieving superior performance compared to a castable without magnesium oxide. To improve the slag penetration resistance of the alumina-spinel castable, suitable for different smelting conditions, an appropriate amount of wax stone (<1mm) was added to the castable. During use, the SiO2 in the wax stone formed a viscous film near the working surface, inhibiting slag penetration. To capture SiO₂ infiltrated by the slag, the insoluble mineral Ca₃(PO₄)₂ is added to the material, effectively suppressing structural spalling.To improve the spalling resistance of alumina spinel castables, appropriate amounts of crushed coarse fused corundum particles, fine zirconium corundum powder, or unstabilized ZrO₂ are added to introduce microdefects into the matrix, absorbing thermal stress and enhancing the castable’s thermal spalling resistance.

Cross-sectional measurements of spent material at Kawasaki Steel’s Mizushima Works in Japan revealed that cracking occurred parallel to the working surface, at the interface between the slag-infiltrated and non-slag-infiltrated layers. These observations indicate that internal stresses are generated at the interface due to the differential expansion between the slag-infiltrated and non-slag-infiltrated layers, and this cumulative cracking indicates that this spalling originates from structural spalling. Internal stress in refractory materials increases with increasing elastic modulus and thermal expansion coefficient, as well as with increasing temperature. The internal stress caused by structural spalling can be characterized by the differential expansion between the slag-infiltrated and non-slag-infiltrated layers and the subsequent changes in elastic modulus and temperature. Therefore, by reducing the differential expansion between the slag-permeable and slag-free layers, as well as the corresponding elastic modulus and temperature variations, stress generation can be reduced and structural spalling can be suppressed. On the other hand, preventing slag penetration is also a method for suppressing structural spalling. To improve the spalling resistance of alumina-spinel castables, appropriate amounts of coarse fused corundum particles, fine zirconium corundum powder, or unstabilized ZrO2 are added to introduce microdefects into the matrix, absorbing thermal stress and improving the castable’s thermal spalling resistance. He Zhiyong et al.’s research suggests that adding 3% zirconium oxide to a corundum-spinel castable significantly improves thermal shock resistance, driven by microcrack toughening. Mori Jun’ichiro et al. reported that controlling the CaO/SiO2 ratio in the castable within the range of 2-10 and the MgO/CaO ratio within the range of 1-24 significantly reduces the rate of ladle lining damage, resulting in less cracking and spalling than with conventional alumina-spinel castables, thereby improving the durability of the ladle lining.

Requirements for refractory materials in cord steel smelting ladles

Numerous factors influence the presence of non-metallic inclusions in cord steel, including steelmaking time, refractory composition, slag composition, deoxidizing alloy composition, and pouring operations. Refractory materials are a significant external source of non-metallic inclusions in cord steel. Throughout the steelmaking process, molten steel maintains constant contact with the refractory lining, subjecting them to constant damage due to dissolution, penetration, erosion, and scouring. Products formed by the erosion of molten steel and slag on the refractory material are exfoliated from the refractory surface and drawn into the molten steel as finely dispersed particles, exhibiting significant compositional changes compared to the original refractory material. Numerous literature reports indicate that refractory materials are a significant source of large inclusions in steel during the steelmaking process, accounting for 70% to 75% of these externally introduced large inclusions. The highest proportion of inclusions is formed when the ladle lining refractory material is eroded by molten steel and then enters the molten steel. The composition of inclusions formed by refractory inclusions can be broadly divided into two categories[27]. First, fragments of refractory material are directly entrained into the molten steel and have not yet been expelled from it. Their composition is largely similar to that of the original refractory material. Second, refractory inclusions are the reaction products between the refractory material and the molten steel or slag. These are formed during the steelmaking and casting process, or when the refractory material is entrained and subsequently becomes the core for further deoxidation and precipitation during cooling and solidification. This significantly changes its composition, and the resulting new inclusion phases are largely different from the original refractory material.

With the development of high-quality steelmaking technologies, such as cord steel, the operating conditions of ladle refractory materials have become increasingly demanding, resulting in a significant reduction in their service life and a significant increase in refractory consumption per ton of steel produced. Furthermore, due to changes in steel grades and the decarbonization of refractory materials, some steel mills have recently experienced a significant increase in ladle slag sticking. Slag sticking to the ladle lining can cause a series of problems for the normal production operations of steel mills, such as ladle overweight, molten steel overflow, shortened ladle life, molten steel contamination, severe localized erosion of the ladle, and puncture accidents.

The selection of refractory materials for the ladle varies depending on the type of steel being smelted. For example, for smelting ultra-low carbon steel, IF steel, and aluminum-killed steel, high-alumina spinel castables or high-alumina bricks are recommended, while carbon-containing magnesia-carbon bricks, alumina-magnesia-carbon bricks, and magnesia-alumina-carbon bricks are not suitable. For smelting steels with high manganese and oxygen content, corrosion-resistant magnesia-carbon bricks and alumina-magnesia-carbon bricks are preferred, while high-alumina bricks are not suitable. Zircon bricks are suitable for casting stainless steels containing Ti and Al. Magnesia-chrome bricks are not suitable for steels requiring extremely low chromium content. Dolomite-based alkaline bricks are preferred for low-P and low-S steels, as well as special steels requiring minimal inclusions, while clay bricks and pyrophyllite bricks are not suitable. When casting rimmed steel, bricks and castables containing graphite should be avoided as much as possible, as otherwise the lining life will be shortened. Therefore, different refractory materials should be selected depending on the type of steel being smelted.

Through the study of refractory materials for ladle, the following research focuses are obtained for refractory materials for cord steel smelting ladles:

(1) Under the premise of ensuring the service life of refractory materials, further reduce the occurrence of Al2O3 inclusions to adapt to new smelting requirements;

(2) Seek new materials that can replace them;

(3) Develop new production processes to prepare refractory materials with special properties that can meet new requirements.