Through analyzing factors affecting ladle service life and safety performance, measures were implemented to enhance both aspects. These included optimizing refractory brick materials, reinforcing critical areas during ladle construction, conducting precise online measurements of residual refractory thickness, refining the composition and structure of ladle refining slag, and applying ladle safety protection technologies. The average total ladle life reached 185 uses, with the highest recorded life reaching 202 uses. This represents an increase of 73 uses compared to the previous average of 112 uses, while both refractory and ladle investment costs decreased significantly. The ladle usage accident rate dropped from 0.6 incidents per 10,000 tons of steel to below 0.05 incidents per 10,000 tons of steel, providing a solid foundation for extending ladle life.

Ladles can be classified into castable ladles and magnesia-carbon brick ladles based on the refractory materials used. Castable ladles exhibit poor slag line resistance to molten steel oxidation, leading to severe erosion of the slag line during refining processes like LF and VD. Their short service life makes them unsuitable for refining steel grades in the converter-LF-VD-continuous casting process route. Magnesia-carbon ladles are primarily lined with neutral Al₂O₃-MgO-C bricks or MgO-C bricks. Within CaO-SiO₂ slag systems, MgO-CaO-C bricks exhibit superior erosion resistance. Al₂O₃-MgO-C bricks and MgO-C bricks demonstrate excellent high-temperature stability, resistance to structural spalling, and resistance to erosion by molten steel and slag. They also possess favorable residual expansion properties, preventing joint cracking even at elevated temperatures. Therefore, they are widely used in all types of refined steel and a certain proportion of refined steel grades.

Currently, the steel mill utilizes magnesium-carbon brick ladles with a capacity of 120 tons and a refining ratio of 60% to 70%. To adapt to market conditions, the mill is adjusting its product portfolio and developing new grades, including: the hard wire series, H08, 70S-6, 77B, 82B, and others. Most special steel grades require LF furnace refining. The harsh operating environment of LF ladles severely erodes the ladles, imposing stringent demands on ladle material quality, repair techniques, and safety protection. As the refining ratio continues to increase, ladles face severe slag line erosion. Erosion at the joints between lining bricks and the mid-section of the lining bricks occurs at significantly different rates. The average ladle life is 112 uses. Concurrently, safety incidents frequently occur during ladle operation. At a monthly production volume of 200,000 tons, ladle accidents reach 10–12 times, resulting in an accident rate exceeding 0.4 incidents per 10,000 tons of steel. Therefore, optimizing ladle service life and safety protection measures will ensure efficient production in converter steelmaking.

1.Factors Affecting Ladle Service Life and Safety Performance

1.1 Cracking of ladle bottom bricks

During operation, the ladle frequently experiences fractures in the bottom refractory bricks, exhibiting significant differences compared to damage in other refractory areas such as the slag line and ladle walls, as shown in Figure 1.

Fractures in ladle bottom bricks pose significant safety hazards during ladle operation. Analysis indicates the following causes: (1) Insufficient ladle curing time. Major-repair ladles require 24 hours of curing before baking, while minor-repair ladles require 12 hours of static curing. Inadequate curing causes rapid temperature rise in the ladle bottom, preventing timely gas venting and resulting in expansion and fracturing of the bottom bricks. (2) Frequent online-offline cycles during ladle operation. Due to significant fluctuations in continuous casting output, the casting machines frequently switch between 1 to 3 units. This subjects the ladle to a “online-offline-online-offline” operational pattern, causing the bottom bricks to reach extreme thermal shock levels and resulting in thermal shock fractures. (3) Diverse steel grades with wide variations in tapping temperature and refining time. The bottom bricks exhibit poor thermal shock adaptability, leading to fractures.

1.2 Severe erosion of ladle walls and slag line

Currently, both the ladle wall and slag line areas of steel ladles are lined with magnesia-carbon bricks. Magnesia-carbon bricks are a composite refractory material composed of high-melting-point basic oxide magnesium oxide and high-melting-point carbonaceous materials resistant to slag penetration, supplemented with various non-oxide additives. They exhibit excellent thermal shock resistance, slag erosion resistance, and slag penetration resistance, making them widely used in the slag line areas of steel ladles. However, traditional magnesia-carbon bricks contain relatively high carbon levels, typically ranging from 10% to 20%. During use, they face issues such as significant carbon enrichment in molten steel and oxidative failure. As carbon content decreases, the bricks’ resistance to erosion, slag penetration, and thermal shock stability are all adversely affected.

During ladle tapping and LF refining, slag line bricks are subjected to intense flow and erosion from molten steel within the ladle. Simultaneously, they endure chemical corrosion primarily from converter slag and refining slag. The main components of Tangshan Iron & Steel Company’s special steel refining slag are: CaO 38%–40%, SiO₂ 31%–34%, Al₂O₃ 4.5%–10.5%, MgO 9.5%–12.5%, FeO 0.86%–1.2%, R (alkalinity) 1.1–1.3. Slag formation for desulfurization is essential throughout steel refining. Desulfurization agents primarily contain fluorite, belonging to the CaF₂-CaO-Al₂O₃ system. The CaF₂-CaO-Al₂O₃ system is typically retained in the molten steel for a certain period to achieve optimal desulfurization. While CaF₂-CaO-Al₂O₃ slag exhibits a low melting point and good fluidity, it causes severe erosion and penetration of refractory materials. Figure 2 shows a photograph of severe erosion at the slag line.

1.3 Inspection of ladles in hot condition

Currently, inspections of ladles in hot conditions rely on the experience of on-site operators. This approach places relatively high demands on operators, requiring a certain level of work experience. Visual inspection methods cannot accurately determine the remaining thickness at critical areas such as the ladle bottom, walls, and slag line. This is particularly problematic for ladles freshly transferred from the continuous casting platform or when residual slag clings to the ladle walls and slag line, severely obstructing operators’ visibility and preventing timely detection of defects in the ladle bricks. Variations in operational experience among personnel can lead to misjudgments of ladle condition, resulting in premature decommissioning. This may even cause abnormal erosion, leading to ladle blowouts or leaks. Minor incidents cause production interruptions, while severe cases can damage equipment due to molten steel exposure, significantly impacting production.

2. Extend Ladle Service Life and Enhance Safety Protection Measures

2.1 Optimization of Refractory Materials for Ladle Bricks

Optimizing the composition of magnesium-carbon bricks involves using electrofused magnesia particles and fine powder with excellent high-temperature resistance and slag erosion resistance as primary components. A multifunctional modified phenolic resin serves as the binder, firmly bonding all raw material components. This yields low-carbon magnesium-carbon bricks with superior high-temperature strength, oxidation resistance, and erosion resistance, thereby extending their service life.

During magnesia-carbon brick production, an aniline-based composite modifier is added. Its molecular structure incorporates rigid benzene rings, phosphite groups, and alumina linked via silane chemical bonds. The aniline groups in this composite modifier participate in the polycondensation reaction of phenol and formaldehyde under alkaline catalysis, successfully modifying the phenolic resin. The resulting modified phenolic resin contains phenyl groups on its molecular chains. formaldehyde under alkaline catalysis, successfully modifying the phenolic resin. The resulting modified phenolic resin molecular chains incorporate benzene rings, phosphite groups, and chemically bonded alumina. The rigid benzene rings enhance the resin’s high-temperature stability and strength, The phosphite groups exhibit excellent high-temperature resistance and also provide auxiliary antioxidant effects. The chemically bonded alumina possesses high-temperature resistance, oxidation resistance, and corrosion resistance, significantly enhancing the phenolic resin’s high-temperature tolerance, oxidation resistance, and corrosion resistance. Consequently, the high-temperature strength, oxidation resistance, and corrosion resistance of low-carbon magnesium carbon bricks are improved.

2.2 Protective measures for critical areas in ladle lining

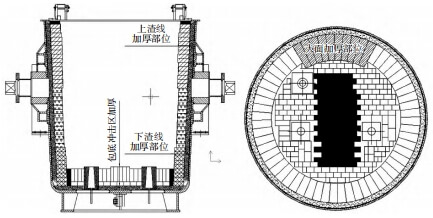

Promote the application of non-uniform bricklaying techniques and optimize ladle repair parameters to achieve uniform erosion across all sections of the ladle. Areas prone to severe erosion include the upper slag line, lower slag line, the large surface of the ladle wall facing slag discharge, and the impact zone at the ladle bottom. For these areas, ladle brick dimensions were adjusted as shown in Table 1. This effectively improved erosion conditions in these zones, achieving uniform erosion across all ladle sections. As illustrated in Figure 3, improvements include thickening the brick profile on the ladle’s slag-discharge surface, increasing the thickness of bricks at the refining slag line, and reinforcing the ladle bottom.

2.3 Precise Measurement of Residual Thickness of Refractories in Online Ladles

2.3.1 Design of the Bottom Measurement Scale

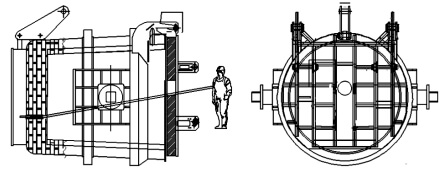

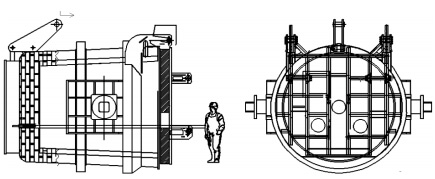

To accurately measure the residual thickness of the ladle bottom and vent bricks, a ladle bottom refractory residual thickness measurement tool was developed. This tool enables precise online measurement of the ladle bottom through a simplified measurement method. The process is as follows: Place the ladle in front of the radiation shield. Observer A inserts the ladle bottom residual thickness measurement tool into the ladle interior from the front of the ladle opening (as shown in Figure 4 below). Observer B monitors the relative position of the scale against the ladle mouth plane from the side. If the scale lies inside or exactly on the ladle mouth plane, the remaining thickness is less than or equal to the minimum set value, indicating the ladle requires removal for repair. Conversely, if the scale extends beyond the ladle mouth plane, the remaining thickness exceeds the minimum set value, permitting continued use of the ladle. This measuring gauge ensures residual bottom thickness measurement accuracy within ±10mm.

2.3.2 Ladle Cover Optimization Design

To enhance measurement accuracy, the ladle cover design has been improved. The original observation hole was positioned at the center of the cover. When the ladle was in the bottom measurement position, the observation hole aligned with the center of the ladle bottom, ensuring accurate bottom measurements. However, a 400mm height difference between the observation hole and the vent brick caused significant measurement errors for the vent brick, as shown in Figure 5. Therefore, two additional measurement observation holes were added to the ladle cover, positioned at the same height as the two vent bricks. This ensures the accuracy of vent brick residual thickness measurements. The original observation hole at the center of the ladle cover is used to measure the impact zone at the ladle bottom, while the added observation holes are used to measure the vent bricks. This improves the measurement accuracy of the ladle bottom residual thickness, as shown in Figure 6 below.

2.4 Optimizing the Composition Structure of Ladle Refining Top Slag

Optimize the composition structure of the top slag in ladle refining to reduce slag line erosion of refining bricks. During refining, molten steel undergoes slag formation and desulfurization. The desulfurization agent primarily consists of fluorspar and lime, belonging to the CaF₂-CaO-Al₂O₃ system. The CaF₂-CaO-Al₂O₃ system is typically retained in the molten steel for a certain period to achieve optimal desulfurization. While this slag exhibits a low melting point and good fluidity, it causes severe erosion and penetration of refractory materials. MgO or MgO-CaO materials require adjustment to enhance resistance against CaF₂-CaO-Al₂O₃ slag erosion. For different refined steel grades, employ LF furnace refining slags with distinct structures. Appropriately increase the slag’s basicity and adjust the fluorspar dosage—reducing per-batch usage from 100 kg to 50 kg—to minimize erosion of the ladle slag line bricks.

2.5 Application of Ladle Safety Protection Technology

2.5.1 Development and application of mechanisms to prevent opening devices

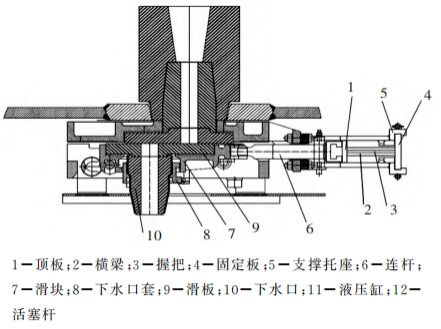

Since the movement direction of the ladle sliding nozzle mechanism aligns with that of the ladle car during steel tapping operations, any slag or debris beneath the ladle car may scrape against the ladle’s lower nozzle. This contact could activate the sliding nozzle mechanism, opening the slide plate and causing a steel leakage accident. Therefore, a protective device to prevent accidental opening of the ladle sliding nozzle mechanism has been invented and developed, as shown in Figure 7. This device can be conveniently installed inside the sliding mechanism, eliminating the risk of slag or slag crust scraping against the sliding mechanism during the withdrawal of the ladle car after tapping, which could cause the sliding plate to open and result in a ladle leakage accident. Specific Operation: After completing hot repairs on the ladle, close the slide plate and remove the hydraulic cylinder. Confirm that the drag block and its slideway are free of residue. Insert the specialized locking tool into the drag block slideway to secure the mechanism’s tie rod. At this point, the mechanism is locked in place and cannot slide. Before initiating continuous casting, remove this device and install the hydraulic cylinder to perform ladle positioning operations.

2.5.2 Prevention of Cracking at Ladle Spout

During operation, the ladle nozzle operates under alternating hot and cold conditions. At high temperatures, it is subjected to pressure from the long nozzle within the ladle’s mechanical gripper, frequently leading to nozzle fractures. Therefore, optimizing nozzle specifications enhances its high-temperature flexural strength. This involves enhancing the reactivity and quality of active reactants (Al, Si, etc.) in the composition, accelerating their reaction rate with carbon at elevated temperatures, and increasing the reaction products. The resulting fibrous microstructure strengthens the matrix-particle bonding, thereby improving the material’s high-temperature toughness and enhancing its high-temperature flexural strength.

2.5.3 Control of Cracking Defects in Base Tiles

The key to preventing cracking in ladle bottom bricks lies in achieving a rational gradation of raw materials, increasing forming pressure, and enhancing the sintering degree of the products. This reduces porosity, increases compressive strength, and boosts carbon content to improve overall strength, erosion resistance, and thermal shock resistance. Concurrently, widening the gaps around the three sets of bricks from 50mm to 60–80mm minimizes the mutual thermal stress impact between ladle bricks and vent bricks.

3. Optimized Ladle Service Life and Accident Rate

Through analyzing factors affecting ladle service life and safety performance and implementing corresponding measures, the average total service life of ladles reached 185 uses, with the highest recorded service life reaching 202 uses—an increase of 73 uses compared to the previous average of 112 uses. The incident rate during ladle operation decreased from 0.6 incidents per 10,000 tons of steel to below 0.05 incidents per 10,000 tons of steel.

4. Conclusion

Following the extension of ladle service life, costs associated with refractories, ladle preheating gas, and tapping temperature have all decreased significantly. Concurrently, through ladle technology optimization, ladle safety has been enhanced, eliminating accidents involving ladle leaks and molten steel spills. Production organization has markedly improved, providing a solid foundation for stable plant-wide operations.