In 2021, China’s domestic steel production reached 1.33667 billion tons, marking a 0.9% year-on-year increase. Continuous casting accounted for over 98% of total output. However, the Chinese steel industry continues to grapple with the dilemma of “excessive low-end capacity and insufficient high-end capacity.” Currently, on one hand, Chinese steel enterprises are experiencing declining profit margins under increasingly stringent carbon emission standards and market competition from homogeneous products. On the other hand, significant imports of certain high-end steel products remain necessary. Amid complex international circumstances, this leaves China’s high-end manufacturing sector perpetually vulnerable to foreign supply chain constraints. Therefore, achieving deep purification of molten steel at lower costs to enable large-scale production of high-quality clean steel holds significant strategic importance for the overall high-quality development of China’s steel industry.

The continuous casting ladle, positioned between the steel ladle and the mold, serves as a critical metallurgical reactor. Originally designed for storing molten steel, stabilizing pressure, and diverting flow, it remains essential for maintaining continuous casting process integrity. As manufacturing demands for steel quality intensify, the ladle’s role in removing inclusions and homogenizing temperature and composition has gained prominence, establishing it as a vital component in clean steel production.

The metallurgical processes within the ladle involve not only molten steel flow but also complex multiphase transport phenomena such as collision and aggregation of inclusions, bubble rise, and fluctuations at the slag-steel interface. Ladle metallurgical technology has evolved around expanding functionalities, primarily encompassing: – Induction heating technology for controlling molten steel pouring temperature ranges – Microbubble argon blowing technology to promote the flotation and removal of fine inclusions – Calcium treatment technology for modifying inclusions – Porous ceramic adsorption technology to enhance inclusion adsorption and removal sealing technology to prevent secondary oxidation of molten steel, and swirling ladle technology to enhance mixing and promote collision-induced agglomeration of inclusions. Extensive research on advanced ladle metallurgy has been conducted by scholars worldwide. This paper comprehensively reviews recent advancements in ladle metallurgy from theoretical research, equipment development, and practical application perspectives.

1.Ladle Flow Control Technology

Optimizing the ladle flow field primarily involves extending molten steel residence time, reducing dead zone volume fraction, and increasing piston zone volume fraction. These measures create favorable flow conditions for the buoyancy removal of inclusions. Additionally, a well-designed flow field stabilizes the liquid surface, minimizing the potential for coating entrainment and air entrainment caused by turbulent impacts. Traditional methods for controlling and optimizing ladle flow fields primarily involve installing flow control devices such as baffles, dams, flow-guiding partitions, and turbulence controllers. The selection of device type, position, and size is critical for optimizing the ladle flow field. Recently, researchers have developed numerous novel flow control devices to better achieve flow field optimization.

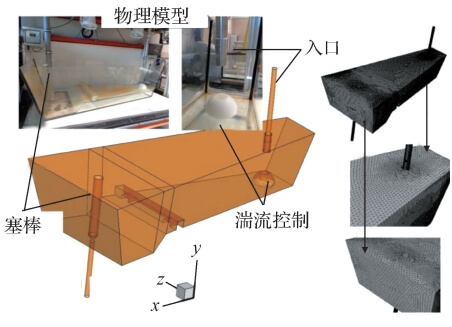

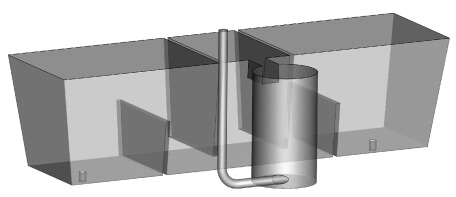

CWUDZINSKI employed numerical simulations and water model tests to investigate ladle fluid characteristics using traditional turbulence controllers versus SFCs (spherical hemispherical turbulence controllers). Numerical and physical ladle models are depicted in Figure 1. Turbulence controllers were selected in two specifications: with and without cavities. The results indicate that larger turbulent flow controllers reduce the velocity of molten steel at the ladle bottom, yet exert no significant influence on the circulation flow direction. Within the design range, increasing the hemispherical size enhances cavity depth, thereby lowering flow velocity in the pouring zone. Each 0.05m increase in hemispherical dimension reduces pouring zone velocity by 0.1m/s. The internal cavity of the turbulence controller limits the stagnant flow zone and increases the proportion of piston flow. Altering the molten steel’s superheat within the 1813–1833 K temperature range does not change the overall fluid flow pattern.

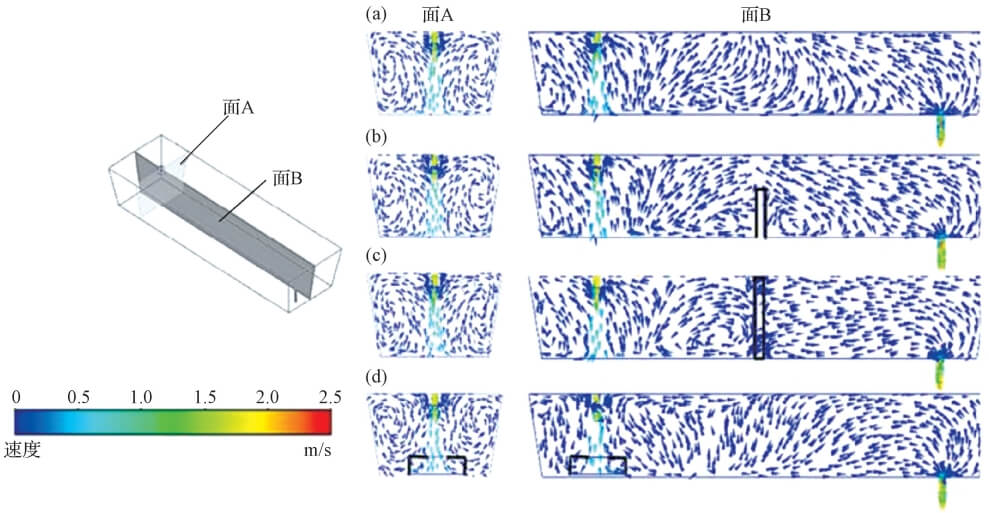

HARNSIHACACHAA et al. investigated the effects of combined structures—retaining walls, dams, weirs, and turbulence controllers—on flow fields through a combination of numerical simulations and hydraulic model tests. They measured tracer concentrations at the outlet to derive the residence time distribution (RTD) curve. The results indicate that circulation phenomena occur in the flow field above the turbulence controller and on both sides of the retaining wall, as shown in Figure 2, where arrows and color intensity represent flow direction and velocity, respectively. Two counter-rotating annular flow structures can be observed on the A-plane.

In Figures 2(a) to (c), the fluid flows at high velocity from the inlet to the bottom of the ladle, separates from both side walls, and flows to the top surface. In Figure 2(d), the circulation direction of the ladle model with a flow stabilizer is opposite to the other three cases, and similar circulation phenomena can also be observed in the corresponding water-based tracer diffusion test. Comparing RTD curves with and without flow control devices shows that the average residence time of molten steel increased from 211 s to 240 s. The combined flow control devices extend the average residence time, allowing inclusions to rise to the molten steel surface and be absorbed by the slag layer, thereby facilitating inclusion removal from the ladle. At JSW Steel’s Vijayanagar plant in India, the combined use of V-shaped and wedge-shaped dams in a 44-ton eight-strand continuous caster increased molten steel residence time by 15% and reduced the overall mass fraction of inclusions in each stream of steel billets by 21%, effectively enhancing inclusion removal capability.

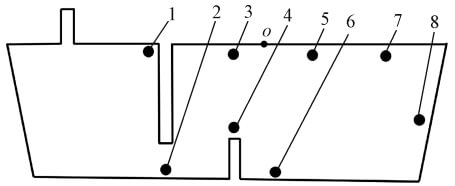

Liu Dongxu et al. employed a combined barrier wall and dam configuration to optimize ladle flow patterns, prolong molten steel residence time, reduce dead volume within the ladle, and enhance inclusion removal efficiency. Numerical simulations avoided using the entire ladle RTD curve for dead volume calculations. Instead, multiple regions were selected within the ladle, with the central axis cross-section (x-y, z=0 section) of the 3D ladle designated as the with the center of the free liquid surface designated as point O. A characteristic point was selected within each region, totaling eight points. The flow behavior of molten steel was assessed based on tracer concentration curves at multiple characteristic points. Figure 3 illustrates the positions of several characteristic points within the ladle. The flow characteristics at these points within each region were examined, with flow velocity used to represent the influence of the flow control device on the internal flow behavior of molten steel. Compared to a ladle without flow control devices, the retaining walls and dams significantly alter the flow paths within the ladle. The retaining walls prevent surface reflux, confine the impact of the pouring stream to a smaller area, reduce slag entrainment, and induce upward flow of the molten steel. This movement carries inclusions to the ladle surface where they are captured by the slag layer, thereby purifying the molten steel. Industrial practice demonstrates that employing an optimized combination of flow control devices stabilizes the ladle liquid surface and significantly improves the removal of medium-to-large inclusions. The total proportion of medium-to-large inclusions exceeding 20 μm decreased from 23.7% to 9.1%, with no large inclusions exceeding 200 μm detected.

Flow control devices can alter the flow path of molten steel within the ladle, improve short-circuit flow phenomena, and effectively suppress the turbulent energy generated during ladle pouring. Existing research on ladle structure optimization primarily focuses on symmetrical ladles. However, some enterprises utilize asymmetrical ladles in actual production, and further study is needed on flow field optimization criteria for asymmetrical ladles.

2.Vortex Ladle Technology

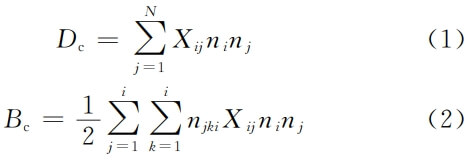

Electromagnetic technology, valued for its eco-friendly, efficient, and non-contact characteristics, is regarded as a crucial method for controlling molten steel flow and has gradually emerged as a distinct research direction within electromagnetic metallurgy. Metallurgical scholars utilize magnetic fields to induce localized vortices within ladles, causing inclusions with lower density than molten steel to be drawn toward the vortex center by centrifugal force, thereby achieving localized enrichment of inclusions. During collision and aggregation, the number of inclusions per unit volume plays a decisive role. The Multi-Scale Group Model (MUSIG) achieves coupling between the group equilibrium model and the turbulence model, making it suitable for calculating particle collision probabilities in low-turbulence viscous fluids. For a given spatial domain, the collision and aggregation behavior of inclusions can be expressed as:

In the equation: Dc represents the proportion of particles lost due to collision-induced aggregation; Xij denotes the aggregation rate between two inclusions; ni and nj denote the number of particles per unit volume; N denotes the total number of particles per unit volume; Bc represents the proportion of particles newly formed by collision; njki denotes the transfer coefficient.

The MUSIG model indicates that the collision probability of small particle inclusions is proportional to the square of their number density. Therefore, local enrichment of inclusions effectively enhances their collision-induced aggregation probability, promoting the coalescence of small inclusions into larger ones. These larger inclusions then rise to the surface via buoyancy for removal, thereby effectively purifying the molten steel.

WANGZM et al. investigated the motion behavior and patterns of inclusions under electromagnetic force by employing an electromagnetic induction device in a ladle. The results indicate that the use of electromagnetic induction ladles significantly enhances the removal of inclusions in steel. Electromagnetic centrifugal ladles represent a novel type of ladle developed to reduce inclusions in steel. Under the influence of a magnetic field, molten steel undergoes rotational motion, generating eddy currents. Inclusions with lower density than the molten steel move toward the center of the rotating flow field due to centrifugal force.

However, electromagnetic vortex ladles require structural modifications that disrupt the original stable flow field within the ladle. Furthermore, the use of electromagnetic centrifugal equipment not only increases energy consumption but also reduces overall system stability, resulting in certain challenges for large-scale application of this technology.

The vortex ladle incorporates a vortex chamber within the pouring zone. When molten steel flows tangentially into the ladle through a long nozzle from the vortex chamber’s base, its gravitational potential energy converts to rotational kinetic energy, inducing holistic rotational flow. Compared to centrifugal ladles, vortex ladles feature simpler construction without requiring electromagnetic stirrers, resulting in lower manufacturing, production, and operational costs. Both ladle types exhibit comparable inclusion removal efficiency. The vortex ladle structure is illustrated in Figure 4. The vortex chamber not only facilitates the flotation and removal of inclusions but also mitigates direct impact of molten steel on the ladle bottom, serving concurrently as a turbulence controller. Vortex ladles deliver outstanding metallurgical performance and hold promising application prospects.

LUJL et al. investigated the collision and aggregation behavior of inclusions within a vortex ladle using a population balance model (PBM). The results indicate that inclusions and molten steel enter the ladle through the nozzle, where small inclusion particles collide with each other to form larger inclusions. The use of a vortex chamber increases the collision probability of inclusions. Collision aggregation enhanced the removal rate of inclusions smaller than 25 μm, while the removal rate of larger inclusions remained largely unchanged. The overall inclusion removal rate increased from 30.09% to 43.20%. This collision aggregation mechanism effectively removes small-particle inclusions, though its influence on the removal of larger inclusions requires further investigation.

3.Ladle Heating Technology

During actual production, when molten steel from the ladle enters the tundish, the tundish’s lining, refractory materials, and walls absorb heat from the molten steel, causing a temperature drop. This temperature fluctuation is particularly pronounced during non-steady-state phases such as the initial pouring stage of the tundish or during ladle changeovers. During production, the casting speed is adjusted during periods of significant temperature change to mitigate fluctuations in molten steel temperature. However, frequent adjustments to the casting speed can cause instability in the liquid level within the mold, shifting the position of the solidification endpoint and leading to casting quality issues, resulting in poor practical application outcomes.

As the final reactor the molten steel encounters before solidification, the ladle’s outlet temperature (i.e., the molten steel’s superheat) directly influences the solidification microstructure, as well as the growth of the shell and the position of the solidification endpoint. Ensuring an appropriate and stable pouring superheat is a crucial prerequisite for improving the microstructure and properties of the cast slab and stabilizing continuous casting operations. Consequently, metallurgical engineers worldwide have begun exploring ladle heating equipment to compensate for temperature variations in molten steel within the ladle, thereby controlling pouring superheat. This approach aims to mitigate temperature fluctuations and draw rate variations during the smelting process. Ladle heating technologies developed in recent years primarily include electromagnetic induction heating, plasma heating, and channel-type induction heating. The characteristics of each process are summarized in Table 1.

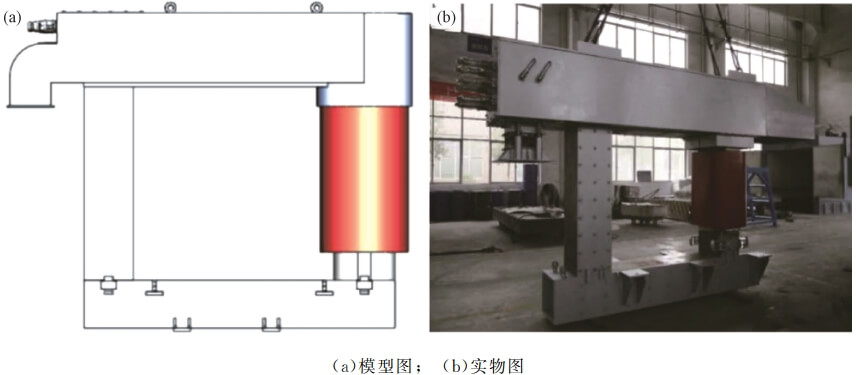

Currently, China has largely achieved independent R&D of induction heating ladles, with successful practical applications in production. Special steel enterprises, in particular, have demonstrated strong recognition of the performance benefits of induction heating ladles. Channel-type induction heating for ladles operates on the principle of electromagnetic induction. The primary assembly consists of an iron core, coils, channels, a protective zone, and a cooling system. An alternating current flowing through the external coils generates an induced magnetic field. This induces eddy currents in the molten steel, causing the charge carriers to move rapidly and randomly. The resulting friction generates thermal energy. Figure 5 shows a schematic diagram and an actual image of the induction heating system. The heating power of the electromagnetic induction coil can be adjusted according to actual production temperature requirements. Wang Kaimin et al. proposed a split-spout channel structure and investigated the effects of channel aperture and angle on molten steel flow through physical simulation methods, comparing it with conventional straight-channel structures. In this study, the split nozzle featured two orifices of 90 mm and 60 mm diameters, respectively, integrated with a dam structure. Results demonstrated that channel-type induction heating significantly improved flow uniformity throughout the ladle, with RTD curves from all nozzles nearly overlapping. Industrial application at a heavy rail steel plant confirmed stable billet quality, with temperature differences between flowing steel ranging from 0 to 3°C, achieving excellent results.

Research by Dou Weixue et al. on induction heating ladles revealed that flow control devices significantly influence molten steel flow, often creating dead zones on both sides of the channel outlet. Employing a combination of retaining walls and dams effectively improves the flow field within induction heating ladles, reduces the proportion of dead zones, and eliminates most short-circuit flows.

Both the thermal effects and electromagnetic forces of induction heating influence the behavior of inclusions in molten steel. Yu Hui et al. conducted numerical simulations of electromagnetic forces and flow fields within electromagnetic induction ladles, combined with industrial trials, to analyze molten steel flow and inclusion removal within the ladle channels. Figure 6 shows the variation in inclusion mass fraction and removal rate at different heating durations. At induction heating durations of 5, 10, and 15 minutes, the inclusion removal rates reached 6.9%, 12.1%, and 22.4%, respectively. Under the interaction of electric and magnetic fields, pressure gradients generated within the melt create force imbalances around inclusions; In the molten metal, inclusions migrate toward the vessel wall. During this movement, they collide, aggregate, and grow larger, ultimately being removed. As heating time increases, the effectiveness of inclusion removal continuously improves. Baotou Steel employed dual-channel electromagnetic induction heating within the ladle during U75V steel production, achieving casting with low molten steel superheat of 15–20°C. The outlet steel temperature fluctuated within ±(2–3)°C of the target temperature, reducing the average carbon segregation index by 0.013 and increasing the proportion of equiaxed grains in the slab from 39.2% to 42%. The proportion of Class B inclusions rated ≤1.0 increased from 88.6% to 90.6%, while Class C inclusions rated ≤1.0 rose from 85.1% to 86.7%. The defect detection rate decreased from 0.32% to 0.30%, effectively enhancing slab quality.

Plasma heating involves energizing the plasma gun and molten steel to form an electric arc between two electrodes. Typically, inert gases such as argon or nitrogen are blown into the arc zone, generating a high-energy plasma stream that heats the molten steel. Essentially, electrical energy is converted into a high-energy plasma stream, transferring heat to the molten steel through radiation and convection. The heating power of the plasma torch is controlled by comparing measurements from temperature sensors against a preset target temperature, utilizing this temperature differential to achieve constant-temperature control of the molten steel. Wang Yong et al. employed a hollow graphite electrode plasma heating device to heat molten steel within a ladle, effectively enhancing heating efficiency. Statistical analysis of inclusions in the ladle steel before and after plasma heating revealed reductions of 7.43% in inclusion count and 19.68% in inclusion density. Plasma heating demonstrably improves the cleanliness of molten steel in ladles. Meishan Iron and Steel Company implemented a 2500kW triple-graphite-electrode DC plasma heating system (heating rate: 0.8–2.0 °C/min) in its twin-stream slab continuous casting machine. Prior to using the heating device, molten steel temperature fluctuations exceeded 40°C during ladle changeovers. After adopting plasma heating, stable casting was achieved with molten steel superheat maintained within 7–13°C. This method offers high heating efficiency and ensures uniform ladle temperature. Sampling analysis before and after heating revealed a decrease in molten steel oxygen content by 0.0001%–0.0016%, an increase in nitrogen content by 0.0001%–0.0003%, with carbon content increasing by an average of 0.0005%. The argon atmosphere between the electrode and molten steel suppressed oxidation. By maintaining the graphite electrode stable above the molten steel, carbon enrichment during heating was prevented.

Currently, induction heating ladle technology is developing rapidly in China and has been swiftly adopted by major enterprises. It possesses relatively mature core technologies, demonstrating excellent results in terms of economic efficiency, practicality, and improvements in ingot quality. China’s metallurgical enterprises introduced plasma heating technology relatively late. Industrial practice has not yet achieved ideal results, and its corresponding value has not been fully realized. However, foreign companies possess extensive experience in its application and have achieved favorable economic benefits. In developed countries such as Japan and Germany, plasma heating is more widely adopted. Looking ahead, China’s research level in ladle plasma heating technology still requires improvement. Advancements in ladle heating technology hold significant importance for driving the overall transformation and upgrading of China’s steel industry.

4.Ladle Microbubble Argon-Blowing Technology

The inclusion content in steel is one of the key indicators affecting the quality and properties of ingots, and inclusion control has become a core issue in ladle metallurgy. Conventional inclusion removal is typically achieved through various ladle refining methods. However, molten steel still contains a large number of small inclusions that are difficult to aggregate and grow, and cannot rise to the surface due to their low buoyancy. Deep removal of these inclusions using conventional methods is challenging.

Research indicates that gas bubbles in steel possess the ability to capture, adsorb inclusions, and promote their flotation for removal, thereby achieving deep purification of molten steel. In recent years, metallurgical researchers have conducted extensive studies on bubble-based inclusion removal, primarily focusing on technologies such as the ladle gas curtain barrier and microbubble argon blowing through a long nozzle.

The core principle of the ladle gas curtain dam technology involves strategically placing porous vent bricks at the bottom of the ladle. By introducing argon gas into these bricks, a gas curtain dam perpendicular to the molten steel flow direction is formed. Additionally, this gas curtain dam alters the flow direction of the molten steel, thereby extending its residence time within the ladle. Replacing traditional physical barriers or dams with the gas curtain wall reduces refractory erosion, lowers the generation rate of secondary inclusions, and enhances molten steel cleanliness. Wang Biao investigated the effect of gas curtain wall technology on ladle residence time using water simulation tests. He discovered two counter-flow zones forming on opposite sides of the gas curtain wall, altering the flow direction of molten steel and optimizing the ladle flow field. HOLZINGERG et al. investigated the removal of non-metallic inclusions by argon bubbles in ladles through water-mold experiments. Results indicated that argon bubbles not only alter flow conditions within the ladle but also directly capture inclusions through surface adsorption upon collision. NIGANA et al. employed numerical simulation to analyze the effects of gas curtain barriers on ladle flow fields, temperature distribution, and inclusion trajectories. Results demonstrated significantly enhanced inclusion removal rates due to upward currents induced by bubble plumes in adjacent molten steel. Laiwu Steel implemented gas blowing through porous bricks at the bottom of 30-ton ladles to form gas curtain barriers in the melt pool. Results demonstrated that slabs without bottom argon blowing contained 100μm inclusions. After bottom blowing, no inclusions larger than 60μm were detected in the slabs, while the mass fraction of inclusions smaller than 20μm decreased by 24%. The average total oxygen content in the molten steel decreased by 15%, clearly indicating the effective removal of inclusions by bubbles.

The bubble size in a gas curtain barrier depends on the wettability at the interface between molten steel and refractory materials. Under non-wetting conditions, bubbles tend to expand laterally along the surface of the pores. Consequently, bubbles formed in actual molten steel typically exceed 1 cm in size, resulting in poor removal of fine inclusions. Furthermore, large bubbles rising in clusters can impact the slag-steel interface, forming slag eyes. This leads to negative effects such as slag entrapment, secondary oxidation of molten steel, and temperature loss. To address these issues, Nippon Steel implemented argon blowing through porous vent bricks in the ladle’s flow zone. This technology utilizes turbulent molten steel in the flow zone to break bubbles, while the dispersed micro-pores in the porous vent bricks control the size of initial bubbles formed by the injected argon. However, the pouring zone experiences intense impact from the molten steel flow, and the porous vent bricks exhibit weaker erosion resistance than traditional ladle linings, resulting in poorer equipment stability. Figure 7 shows a schematic diagram of Nippon Steel’s ladle pouring zone argon injection technology.

Long nozzle argon blowing is a novel micro-bubble argon blowing method, initially designed to compensate for the negative pressure formed by molten steel injection through the long nozzle and prevent gas absorption and oxidation of the steel. Aring-shaped vent bricks at the top of the long nozzle inject argon gas. The shear action of the high-velocity fluid forces bubbles to detach from the vent holes, effectively suppressing interfacial effects during bubble formation. The generated bubbles are further fragmented and refined by turbulence within the pouring zone, resulting in the formation of a large number of finely dispersed microbubbles within the ladle. The size of bubbles in the molten pool depends on the initial diameter of bubbles detached from the pore in the shear flow and the degree of turbulent fragmentation.

The bubble detachment behavior from pores in the shear flow can be characterized by the empirical formula proposed by MARSHALL (Equation (3)), where the initial bubble diameter depends on the gas flow velocity, pore diameter, and fluid flow velocity. The ideal assumption for determining the critical diameter for turbulent breakup using the Weber number is that the bubble remains under constant turbulent dissipation for an infinite duration. The actual turbulent-ruptured bubble size lies between the initial bubble diameter and the critical turbulent rupture diameter. The degree of incomplete turbulent rupture depends on the bubble’s residence time in the turbulent rupture zone and the distribution of turbulent dissipation rates along the bubble’s trajectory.

In the equation: ds is the initial bubble diameter, m; Rport is the pore radius, m; u is the fluid velocity, m/s; uair is the gas velocity, m/s; dt is the bubble diameter at a given turbulence dissipation rate, m; Wec is the critical Weber number; σ is the liquid surface tension, N/m; ρ is the fluid density, kg/m³; ε is the turbulence dissipation rate, m²/s³; db is the final bubble diameter, m; C is the model constant; Δε is the rate of change of turbulence dissipation rate, m/s³.

To maintain the small size of microbubbles and ensure their extensive distribution within the ladle, CHANGS et al. designed a novel impact plate to replace conventional turbulence controllers. Based on this, they investigated the effects of turbulence controllers and impact plates on inclusion removal efficiency. A mathematical model was established to simulate bubble motion within the ladle, accounting for bubble collisions and coalescence. Both the turbulence controller and impact plate demonstrated similar performance in improving the flow field. However, compared to the turbulence controller, the impact plate effectively reduced the collision probability between bubbles, expanded the distribution range of bubbles within the melt pool, and decreased the average bubble size in the ladle. The results indicate that the use of microbubble argon blowing through a long nozzle reduces the residual quantity of inclusions smaller than 51 μm in diameter by 53.9%, effectively improving the cleanliness of molten steel. Liu Jianhua et al. employed long nozzle argon blowing technology in continuous casting production. They conducted online sampling of molten steel in the pouring zone using the “cold steel strip wiping method,” analyzing internal bubbles in solidified steel via scanning electron microscopy and confocal microscopy. The results indicate that the bubbles generated by the long nozzle argon blowing technique range in size from 100 to 1000 μm, with an average size of 500 μm. Analysis of the composition of inclusions in the samples revealed that CaO(-MgO-)Al₂O₃-SiO₂ composite inclusions are less likely to be captured than Al₂O₃ inclusions.

5.Ladle Filter Technology for Impurity Removal

Removing small particulate inclusions from steel through molten steel filtration has emerged as a new direction in ladle metallurgy technology in recent years. This process is simple to operate and effectively purifies molten steel. Porous ceramic filters currently represent an efficient and relatively low-cost filtration device. This technology leverages the adsorption effect of porous ceramic surfaces on inclusions, enhancing removal rates and thereby improving slab quality with significant economic benefits. A model of the porous filtration device is shown in Figure 8. Related studies indicate that the removal rate of inclusions is influenced by the filter material, pore diameter, thickness, and molten steel flow velocity.

The primary types of filters include ceramic foam filters, porous filter plates, and filter tubes. Their materials mainly consist of CaO, Al₂O₃, ZrO₂, ZrO₂-Al₂O₃, MgO, Al₂O₃-C, and mullite. Relevant studies indicate that filters demonstrate highly effective removal of large-particle inclusions. In industrial production, Xinyu Iron and Steel employs right-angle tubular calcium filters (60 mm diameter) during the smelting of non-oriented silicon steel. This effectively removes Al₂O₃-type inclusions from molten steel. White Al₂O₃ inclusions are clearly visible adsorbed within the filter core. Prior to filter implementation, the maximum total oxygen mass fraction in the steel reached 0.0053%. After porous ceramic filtration, the total oxygen mass fraction in the pouring zone for four furnace batches decreased to 0.0025%, 0.0030%, 0.0015%, and 0.0040% respectively, demonstrating a significant purification effect on the molten steel. Testing of CaO straight-hole filters at Liugang Steel Mill reduced inclusions in steel by 20%. After adopting magnesium-based through-hole filters at Benxi Steel, the mass fraction of inclusions in finished billets decreased by over 50%.

Based on zirconia ceramic filters from Nanjing Iron and Steel, LIM et al. analyzed the content, types, shapes, sizes, and compositions of nonmetallic inclusions in steel, evaluating the inclusion removal capability of ladle ceramic filters.

The results indicate that filter material selection depends on the composition and size of particles to be removed. Higher alumina content on the filter surface captures more alumina-based nonmetallic inclusions. These findings demonstrate the dependence of filtration efficiency on both nonmetallic inclusions and the chemical properties of the filter material. The mechanism for removing nonmetallic inclusions in the filtration mode is related to collision and interception effects on the wall surface. Hydrodynamic simulations of inclusions adhering to the filter wall indicate that most inclusions, especially larger ones, are retained in the upper part of the filter, while smaller inclusions are well dispersed throughout the filter. Filtering the melt through an alumina-based ceramic medium significantly reduces the number of inclusions in the molten steel. Overall inclusion removal efficiency depends on the filter material, the velocity of molten steel through the filter, the filter height, and the inclusion size. The continuous casting billet pulling rate and inclusion density have a relatively minor impact on the capture rate.

6.Ladle Microalloying Technology

During continuous casting, alloying the molten steel is a crucial method for enhancing steel properties. Specifically, adding trace elements or nonmetallic inclusion modifiers to the molten steel has become an essential technique for producing high-quality ingots. Ladle microalloying originated in the 1950s with the concept of adding nickel to the ladle. By regulating fluid dynamics through flow control devices, molten steel entering the ladle serves as a carrier for alloying elements. Turbulence within the injection zone ensures thorough mixing of alloy additives with the liquid steel. The pulse-stepping method achieves rapid microalloying and homogenization of molten steel.

CWUDZINSKI investigated the microalloying process of steel elements in a two-stream slab ladle. The pulse-stepping method was employed to introduce alloys into the molten steel, considering five flow control devices and alloy feed positions. The two-stream slab ladle configuration is shown in Figure 9. Comparisons were made regarding the molten steel flow field, alloy concentration time-varying curves, dimensionless mixing time, and alloy concentration deviation at the ladle outlet. The study indicates that simultaneous alloying at multiple positions is more conducive to achieving uniform distribution of alloying elements in the molten steel.

Adding alloying elements to molten steel in the ladle enables precise control of the final composition of the ingot, thereby achieving the production of high-quality steel. Research in China on ladle microalloying is still in its infancy, and further study is needed on the element mixing time in the ladle and the alloying methods applicable to ladles with different structures.

7.Conclusion

Ladle metallurgy is a critical component in clean steel production. As demands for steel quality continue to rise, the functions of ladle metallurgy are constantly expanding and improving. Beyond its original roles of storing molten steel, diverting flow, continuous casting, and pressure reduction, it must now also perform new functions such as removing inclusions, controlling steel superheat, and promoting molten steel homogeneity. Researchers have developed new technologies such as ladle induction heating, microbubble argon blowing through long nozzles, and vortex ladles to enhance these evolving metallurgical functions, effectively elevating the ladle’s metallurgical capabilities. Typically, the application of new technologies introduces additional challenges. For instance, microbubble argon blowing carries the risk of inducing slag holes, while induction heating alters the ladle’s original optimal flow control structure. How to introduce new technologies while reasonably mitigating their negative effects remains a key issue requiring further resolution in ladle metallurgy research. Furthermore, critical periods for molten steel contamination and temperature fluctuations include ladle replacement, ladle pouring initiation, and the final stage of ladle pouring. In-depth investigation of multiphase transport phenomena during these transient processes and the development of targeted optimization strategies are crucial for enhancing the stability of ingot quality.