Overview of bottom-blown air-permeable bricks

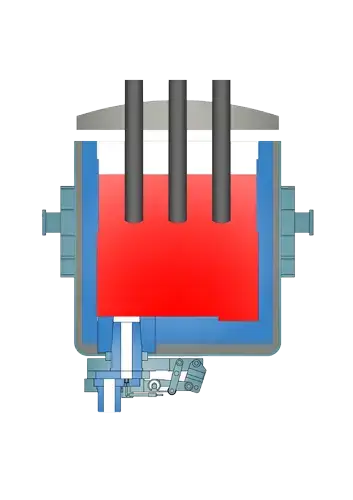

Since the 1960s, the ladle secondary refining process has been used by various steel producers. Production practice has proven that secondary smelting in the ladle is difficult without effective inert gas treatment. Initial inert gas stirring was achieved using a top-blown argon lance, but its stirring effect was significantly limited, making it difficult to fully stir the molten steel near the bottom of the ladle. Bottom-blowing can enhance molten pool stirring, removing non-metallic inclusions, purifying the molten steel, and achieving uniform composition and temperature. Domestically, permeable bricks have been used for secondary refining since the 1970s. By the 1990s, the use of bottom-blown argon technology with permeable bricks had become a key smelting method for steel companies.

Metallurgical functions of breathable bricks

The ladle air brick is the most critical functional element in the secondary refining process. Its main functions are as follows:

(1) It can adjust the uniform distribution of the molten steel temperature in the ladle to achieve the optimal casting temperature of the existing process.

(2) The alloy and deoxidizer in the ladle can be evenly distributed through blowing and stirring.

(3) Non-metallic inclusions in the molten steel can be brought into the slag to meet the cleanliness requirements of the molten steel.

To achieve the above functions, the inert gas used for refining needs to be blown into the ladle through the air brick. At the contact surface between the air brick and the molten steel, that is, the working surface of the air brick, a large number of bubbles blown out under sufficient pressure form a gas jet beam, stirring the molten steel in the entire ladle, promoting the flow of the molten steel, and making the temperature and composition in the ladle uniform. At the same time, the continuously ejected bubbles bring the non-metallic inclusions in the molten steel into the slag under the action of the interface, thereby achieving the purpose of clean molten steel.

Performance that breathable bricks should have

In order to meet the above-mentioned metallurgical functions, air bricks must have the following main properties:

(1) Good air permeability. Air permeability is one of the important parameters for measuring the quality of air bricks. Studies have shown that the stirring energy of molten steel is proportional to the flow rate of the gas blown in; the stirring energy directly affects the stirring efficiency of molten steel, and only sufficient stirring energy can achieve a good stirring effect on the molten steel. When the amount of argon blown is constant, the more argon bubbles blown out, the more beneficial it is to the degassing and stirring of the molten steel.

(2) High-temperature corrosion resistance. The refining ladle has very strict requirements in terms of temperature and time. The highest temperature often reaches above 1750℃, and the refining time sometimes reaches tens of minutes. During the refining operation, the alkalinity of the slag has a great influence on the life of the air brick. Therefore, the air brick will be corroded by the alkaline slag with strong permeability at high temperature and will be damaged quickly.

(3) High-temperature wear resistance. When the bottom of the refining ladle is blown with argon, the flow speed of the molten steel in the ladle is very fast due to the bottom blowing of argon, and the erosion and wear of the lining material and the bottom air bricks and seat bricks by the molten steel is significantly increased. When the ladle is hot repaired, in order to remove the residual steel and slag on the surface of the air bricks and restore the air permeability of the air bricks, it is necessary to blow oxygen to clean the surface of the air bricks to melt the steel slag adhering to the surface of the air bricks; at the same time, blow gas into the air bricks to blow away the slag. During the cleaning process, the air bricks are eroded by high-speed air flow, so the air bricks are required to have good high-temperature wear resistance.

(4) Good thermal shock resistance. Since the ladle is intermittently operated, when the ladle is poured with molten steel, the end of the air brick is affected by the high-temperature molten steel, and the temperature rises sharply. When argon is blown, it is cooled by the cold air flow, and a large thermal stress is generated inside the material. At the same time, when molten steel is injected into the empty ladle, a large temperature change will also occur. Therefore, the use conditions of the air bricks are very harsh, and thermal peeling and structural peeling are very easy to occur.

(5) Easy installation, safe and reliable. The air bricks are installed inside the base bricks at the bottom of the ladle. The working conditions are extremely harsh. The life of the air bricks cannot keep pace with the life of the entire ladle. Therefore, the air bricks need to be replaced. Therefore, the installation operation must be simple and the use must be safe and reliable to avoid the occurrence of steel seepage and leakage.

Structural development of breathable bricks

After years of development, air bricks have evolved into three common structural types: diffused, slit, and straight-through.

Diffused air bricks are the earliest form of air brick. Due to the high porosity of the material, the numerous pores provide a path for inert gases. However, the disadvantages of this porous surface-diffused air brick include low strength, poor erosion resistance, susceptibility to penetration by molten steel and slag, and flaking, as well as poor stirring of the molten steel. Currently, they are rarely used in domestic ladle air bricks.

Slit air bricks come in two forms. One is a “jointed” type, in which the central slit is formed by assembling several thin, molded sheets, and the exterior is cast with castable material. This type of air brick has the disadvantage of poor controllability of the injected gas. The other type, commonly known as the “slit” type, precasts dozens of straight-through slits throughout the brick body. Compared to the slit type, the slit type offers advantages such as a longer lifespan, a higher blow-through rate, a larger air flow rate, and improved stirring.

Straight-hole air bricks are made by embedding varying numbers of thin steel tubes within the brick. The gas passages consist of numerous straight, microscopic tubes, and are cast using a casting method. Compared to diffused air bricks, straight-hole air bricks offer superior mixing performance and a service life that’s 2-3 times longer. However, their drawback is their limited gas flow rate. In later life, refining often fails due to reduced air flow or impermeability.

Installation options for air bricks

The placement of air bricks is determined by the volume of molten steel in the ladle, the quality requirements of the steel being smelted, and the process route. The location of the bottom blowing assembly in the steel mill should be determined based on the intended ladle handling. Argon blowing at the center of the ladle bottom and off-center (at a point 1/2 to 1/3 the radius from the center) produces different stirring effects on the molten steel. Argon blowing at the center of the ladle bottom promotes reactions between the slag and the molten steel, as well as desulfurization of the top slag. Argon blowing at an off-center location promotes mixing within the ladle, evens out the temperature, and allows inclusions to float. For example, air bricks in CAS/CAS-OB furnaces need to be installed at the center of the ladle bottom because this process requires argon to open the molten steel slag surface below the impregnation hood to facilitate alloying or oxygen injection during smelting. LF furnace processes, on the other hand, require air bricks to be installed near the bottom of the LF furnace door to facilitate operations such as carburization, alloying, and deoxidation. The more ladle air bricks installed, the more small bubbles are generated, the more effective the inclusion removal is, and the better the molten steel quality. However, the greater the number of air bricks installed, the greater the risk of steel leaks. Generally, when smelting plain carbon steel, a single air brick is sufficient for ladles under 70t; ladles over 70t require two air bricks.

Air bricks can be installed in two ways: internally or externally. The internal installation method involves pre-assembling the air bricks and base bricks outside the ladle. During ladle construction, the position for the air bricks on the ladle bottom is cleared. After the curtain bricks are laid, the air bricks with base bricks are hoisted into position. The ladle bottom and ladle lining are then constructed. The external installation method consists of base bricks, cover bricks, and air bricks. When constructing a ladle, after installing the base bricks, the base and walls can be constructed. Finally, the outer surfaces of the lining bricks and breather bricks are evenly coated with fire clay and firmly installed into the base. Pad bricks are then placed underneath the lining bricks and breather bricks, and the flange is closed before baking. Internally mounted breather bricks are used when the lifespan of the ladle lining bricks and breather bricks are synchronized, while externally mounted breather bricks are suitable for situations where frequent replacement of breather bricks is required. Due to the low safety and reliability of internally mounted breather bricks, as well as the difficulty of replacement, almost all ladles currently use externally mounted breather bricks.

Materials and uses of breathable bricks

Currently, the materials of breathable bricks include corundum, chrome corundum, high alumina and magnesium chromium.

Corundum-spinel system breathable brick

Single-phase corundum castables have suboptimal slag and thermal shock resistance, while spinel materials offer excellent resistance to slag erosion. Based on the principle of improving refractory performance through multiphase modification, high-purity fused spinel is added to corundum castables to improve their performance. The raw materials used are plate-shaped corundum as granules, fused white corundum, spinel, and active α-Al2O3 micropowder as fine powders, and calcium aluminate cement as a binder. This method offers significant improvements in thermal shock and slag resistance. However, its disadvantage is that during high-temperature treatment, the spinel undergoes volume changes, resulting in poor volume stability and difficulty controlling the volume during production.

Corundum-chromium oxide system breathable brick

To further enhance the air brick’s resistance to slag corrosion, a certain amount of chromium oxide powder is added to the product. The main raw materials are tabular corundum as granular material, tabular corundum fine powder and chromium oxide fine powder as fine powder, and calcium aluminate cement as a binder. At high temperatures, chromium oxide and aluminum oxide form a high-temperature solid solution, while a small amount of magnesium oxide forms a partial solid solution, MgO·Cr2O3-MgO·Al2O3. This solid solution significantly enhances its resistance to erosion by Fe2O3 or slag, and its high viscosity effectively prevents slag penetration and erosion at high temperatures. Furthermore, a small amount of Cr2O3 can inhibit excessive Al2O3 growth, reduce stress within the crystals, and improve the material’s physical properties. However, if added in excessive amounts, the growth of the corundum grains will be excessively inhibited, generating internal stresses that will degrade the material’s physical properties. Furthermore, Cr2O3 is relatively expensive, and adding too much can significantly increase costs. Furthermore, Cr2O3 poses a serious environmental risk.

Corundum-spinel system breathable seat brick

Corundum-spinel-based breathable bricks are the most widely used material. Their main raw materials are plate-shaped corundum, α-Al2O3 powder, and spinel, combined with pure calcium aluminate cement. Their advantages lie in their excellent performance, due to their strong resistance to acids and alkalis and their high melting point. Magnesium-aluminum spinel is highly resistant to alkaline slag and relatively stable against iron oxides. When in contact with magnetite at high temperatures, it reacts to form a solid solution, improving the high-temperature corrosion resistance of the bricks. Furthermore, spinels containing solid solutions of MgO or Al2O3 exhibit enhanced thermal shock resistance due to differences in expansion coefficients between the minerals. However, their disadvantage is that when MgO and Al2O3 form spinel according to their theoretical composition, the volume expansion is approximately 8%, making densification difficult during firing and the volume change of the bricks difficult to control.

Corundum-chromium oxide system breathable seat brick

Corundum-chromium oxide-based breathable base bricks are based on the corundum-spinel system and are developed to improve the high-temperature spalling resistance of breathable base bricks. The main raw materials are plate-shaped corundum, a-Al2O3 micropowder, industrial chromium oxide, and spinel, combined with pure calcium aluminate cement. Their advantage lies in the significant increase in corrosion resistance to iron oxide slag from the solid solution formed by the Al2O3-Cr2O3, while the spinel improves the base brick’s performance. The addition of a small amount of Cr2O3 inhibits the excessive growth of alumina crystals, thereby reducing internal stress and improving the thermal shock, erosion, and corrosion resistance of the breathable base bricks. However, the disadvantage is that excessive addition of Cr2O3 severely impacts the growth rate of the corundum grains, thereby reducing the material’s physical properties. Furthermore, Cr2O3 poses a serious environmental risk, violating national sustainable development requirements.

Damage mechanism of breathable bricks

The work of air bricks is a discontinuous operation. Different physical and chemical corrosion will occur at different times during the entire ladle turnover cycle. From a practical point of view, the damage of air bricks can be divided into the following types:

(1) Oxygen purging effect

After the ladle is finished tapping and before the next steel is received, the ladle is hot-repaired in the hot-repair area. At this time, the working surface of the air bricks needs to be purged with oxygen to clean the steel and slag remaining on the working surface. Oxygen purging is beneficial to the normal use of the air bricks. This measure ensures the cleanliness of the working surface of the air bricks and the smooth flow of gas channels, so that the ladle turnover cycle can proceed smoothly. However, since it is difficult to accurately grasp the thickness of the steel and slag remaining on the working surface of the air bricks in the hot-repair area, after removing the residue, the air bricks may be accidentally burned. When the bottom of the ladle is in poor condition or the operator in the hot-repair area makes a mistake in judgment, the situation may be more serious. When the oxygen is burned, the temperature reaches above 2000℃. The high-temperature airflow is very fatal to the air bricks. The amount of melting loss in these few minutes is often 2 to 3 times higher than the normal refining erosion.

(2) Mechanical wear effect

During the tapping process, the high-speed and strong scouring of the bottom of the steel tank by the molten steel will also accelerate the wear of the air bricks. Some people have studied the wear of air bricks through hydraulic model tests and found that when a low-speed air flow is injected into the liquid phase molten pool, the air flow hits the front edge of the air brick, exerting a certain impact force on the refractory material around the outlet. When the gas flow rate is further increased, the frequency of the reverse pulse decreases, but the intensity of the reverse impact further increases. In addition, when the argon blowing enters the normal injection state, strong bubbles form a gas jet beam, which strengthens the stirring at the bottom of the steel tank and intensifies the liquid phase movement at the bottom of the steel tank. The two-phase vortex causes the air brick to be subjected to strong shear and impact stress. The shear and scouring of this vortex is particularly obvious when the air brick is higher than the base brick. The part above the base brick is generally washed away after a single use. Therefore, this situation is often easy to occur when the air brick is newly replaced. In addition, if the valve is closed quickly after refining, the reverse impact of the molten steel will also accelerate the damage of the air brick.

(3) Effect of thermal stress

The refractory materials on the working surface of the air-permeable brick, especially those around the outlet, are in direct contact with the high-temperature molten steel and are affected by the high-temperature molten steel and the continuously flowing cold air flow, resulting in a large temperature gradient. Due to repeated use, the air-permeable bricks are subjected to large rapid cooling and heating effects, especially the areas near the outlet, which are subject to greater thermal stress, making them prone to annular cracks and fractures.

(4) Chemical erosion

The working surface of the air-permeable brick is in contact with the slag and molten steel for a long time. During the entire service life, the slag continuously infiltrates and penetrates into the bricks. Oxides such as MnO, MgO, SiO2, FeO, and Fe2O3 in the molten steel and slag react with the bricks:

12CaO 7Al2O3═12CaO·7A1203

FeO Al2O3═FeO·Al2O3

2MnO SiO2 Al2O3═2( MnO)·SiO2·Al2O3

The generated FeO·Al2O3, 2(MnO)·SiO2·Al2O3, 12CaO·7A12O3 and other low-melting materials are washed away, causing the breathable bricks to be corroded.

Ways to increase the life of air bricks

(1) Adding zirconium-based materials and plate-shaped corundum to improve the spalling resistance of breathable bricks.

Adding pre-synthesized zirconium-based materials to breathable bricks can modify aluminum-chromium breathable bricks. Corundum materials and zirconium-based materials have different linear expansion coefficients. Microcracks are formed under high temperature conditions, which play a role in absorbing and releasing part of the energy of the main cracks, reducing stress concentration, inhibiting crack expansion, and increasing the toughness of breathable bricks. Adding pre-synthesized zirconium-based materials and utilizing the toughening effect of ZrO2 can significantly improve the thermal shock resistance of breathable bricks. Plate-shaped corundum is a sintered alumina raw material that shrinks more thoroughly without adding any additives such as MgO and B2O3. Its physical phase is composed of hexagonal plate-shaped α-Al2O3 crystals with a median diameter of 40 to 20 μm. The two-dimensional morphology of the crystals is interlaced with each other in the form of flat plates. During rapid sintering, the coarse crystals formed by the recrystallization of submicron-sized α-Al2O3 contain 5 to 15 μm round closed spherical pores. Therefore, the high strength of tabular corundum gives breathable bricks excellent thermal volume stability and good thermal shock resistance. Reducing impurity content can improve the erosion resistance of breathable bricks. When high-temperature oxygen combustion removes steel slag from the surface of breathable bricks, the slag, under the influence of high temperature, easily reacts with the refractory material, forming erosion pits. The higher the impurity content in the refractory material, the more severe the oxygen erosion. Therefore, it is necessary to minimize the impurity content of the refractory material to improve the high-temperature resistance of the breathable brick. Reducing the impurity content of breathable bricks can be achieved by selecting low-impurity R2O raw materials and reducing the amount of cement added to the breathable brick castable. Lowering the cement content reduces the CaO content, which reduces the amount of low-melting-point grosslandite, resulting in improved refractory performance and enhanced resistance to oxygen purge and erosion.

(2) Ultrafine powder is preferred.

To improve the strength of breathable bricks, α-Al2O3 micropowder is one of the main raw materials of breathable bricks as a binder. At high temperatures, α-Al2O3 micropowder can promote the sintering of materials, improve the strength of breathable bricks, and help enhance the ability to resist oxygen purge.

(3) The stirring intensity of molten steel is proportional to the amount of argon blown.

The more bubbles blown out from the slit, the greater the stirring intensity, and the more beneficial it is to the degassing of molten steel. Therefore, the selection of the slit width of the breathable brick is extremely important. When the slit is too narrow, it will not be blown open during use due to the small air permeability and cannot be turned over; when the slit is too wide, the bubbles are large, the stirring effect is poor, and it is easy to cause steel infiltration, resulting in the inability to blow open after secondary use. The slit width is the basis for the stable use of breathable bricks. The selection of the slit width mainly considers the relationship between the height of the molten steel and the infiltration of steel. When the height of the molten steel is greater than 2m, the slit width should be less than 0.15mm to prevent the penetration of molten steel.

(4) Uniform distribution improves the volume stability of air bricks.

During the molding process of air bricks, the distribution of castables directly affects the volume stability of air bricks. The slits of air bricks are staggered, and the widths of the slits are different. During vibration molding, aggregates or fine powders are easily concentrated, resulting in uneven volume changes during the use of air bricks. The change in slit width causes the air bricks to be unable to be blown open or steel seepage. There are two solutions: one is to adjust the fluidity of the air brick castable and control the amount of water added to prevent stratification during vibration molding; the other is to fix the slit filler to ensure uniform distribution of castables and avoid deviation during casting molding, which causes local narrowness and difficulty in material removal.