In order to further promote the research on converter steelmaking technology, exchange the application experience of converter high-efficiency and low-cost steelmaking furnace protection technology, and promote new long-life, high-efficiency and environmentally friendly converter furnace protection materials and technologies, we invited well-known experts in the steelmaking industry and enterprise expert representatives to discuss and discuss hot issues.

Slag splashing, gunning and filling to ensure the longevity of the converter

Since 2000, my country’s converter steelmaking production has entered an innovation period. During this period, a major transformation of the traditional converter function was achieved: the desiliconization, dephosphorization and desulfurization reactions were separated from the decarburization, alloying and other functions, achieving the development goals of high efficiency, low cost and ultra-purity.

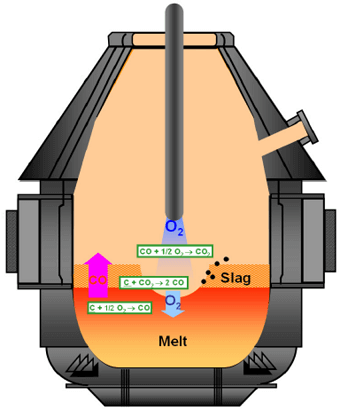

During this period, some converter steelmaking enterprises adopted inert gas weak stirring and top and bottom composite blowing processes to improve the reaction efficiency, and some enterprises adopted strong stirring and composite blowing processes to promote the balance of steel slag reaction.

The slag splashing furnace protection technology, which uses high-speed nitrogen jets to impact the molten pool, splashes the slag and evenly coats it on the surface of the furnace lining, has achieved good furnace protection effects. This technology has greatly increased the converter life from a few hundred furnaces to more than 10,000 furnaces.

The application report on converter lining maintenance and long-life re-blowing technology points out that my country currently adopts a process that combines converter steelmaking with off-furnace refining, which can produce ordinary carbon steel, high-quality steel, and pure steel, which can meet the needs of social progress.

Combined-blowing converter steelmaking is a major advancement of historic significance

After the converter adopts the combined blowing steelmaking process, the converter steelmaking process becomes more reasonable, the reaction is closer to balance, the quality of molten steel is improved, and higher economic benefits are achieved.

The combination of three technologies, namely, slag splashing furnace protection technology, gunning and refilling, has become a key means to ensure the long life of my country’s converters. The combination of various furnace protection processes has become the key to ensure the long life of converters. Its specific effects are reflected in the following aspects:

First, slag splashing furnace protection can spray high magnesium oxide slag evenly on the surface of the furnace lining, especially the lower surface; second, large surface refilling is suitable for repairing the front and rear large surfaces and the bottom of the converter; third, gunning can repair the converter cap and the side of the trunnion. Fourth, the three methods are used in combination to ensure that the erosion of the converter lining is uniform and maintains a good shape throughout the service life. Fifth, the bottom blowing brick quick replacement technology can restore the re-opening of individual failed bottom blowing components.

Another new concept of the combined blowing converter life is: scientific long-life combined blowing furnace life. Enterprises adopt different furnace protection policies according to the product structure of each steel mill; the carbon and oxygen accumulation of molten steel at the end is guaranteed to be within a reasonable range; and the life of the furnace lining is extended as much as possible under the condition of completing the molten steel smelting task. The enterprise adopts a combination of various furnace protection methods to ensure the reasonable application of the combined blowing process, so that the combined blowing converter life can be scientific and achieve the maximum economic benefits.

The combination of combined blowing technology and scientific furnace protection technology has fundamentally changed the concept of converter steelmaking in my country, greatly liberated the production capacity of converters, greatly improved the steelmaking level and converter life, and made my country’s steelmaking technology and various economic indicators at the forefront of the world.

Environmentally friendly carbon-free water-based converter large-surface self-flowing material is well received again

The development and use of environmentally friendly carbon-free water-based converter large-surface self-flowing materials. This self-flowing material uses an environmentally friendly liquid binder, does not contain carbon and low-melting-point substances, has good material fluidity, no toxic smoke during the sintering process, short sintering time and long service life. Its specific characteristics are as follows: environmentally friendly and pollution-free, no toxic and harmful smoke is generated during the sintering process; the material has good fluidity, self-flowing and spreading in the furnace, and there is no need to shake the furnace repeatedly; the sintering time is short, and the time required to sinter 2 tons of material does not exceed 30 minutes; the sintering is sufficient to eliminate the splashing hidden danger caused by the sandwich layer; it does not contain asphalt and will not bring C, S and other pollutants into the molten steel; ceramic bonding, the bonding strength of the oxidizing atmosphere is not affected; the service life can reach more than 3 times that of traditional furnace filling materials; the increase in production and efficiency is significant, usually one furnace can increase steel production by more than 8%, and reduce the consumption of large surface materials by about 70%.

The steelmaking workshop is equipped with three 120-ton converters, and currently has reached a monthly output of 450,000 tons of qualified molten steel. The contradiction between the increase in output and the erosion of the converter condition and the need to protect and replenish the furnace is becoming increasingly prominent. In addition, the current safety and environmental protection situation in the steel industry is becoming increasingly severe. How to improve the efficiency of furnace protection and replenishment, and enhance smelting efficiency, safety and environmental protection have become the focus of the plant’s consideration.

The use of a series of products such as environmentally friendly water-based large-surface self-flowing materials, high-efficiency feeding materials and furnace mouth anti-sticking slag spray coatings has achieved good results.

The average service life of traditional large-surface materials is 31 furnaces, and the sintering time per ton is about 33 minutes. The average service life of environmentally friendly water-based large-surface materials is 87 furnaces, and the average sintering time per ton is 15 minutes, which can effectively shorten the furnace filling cycle and increase furnace hour output. At the same time, environmentally friendly water-based large-surface materials can meet the current strict environmental protection requirements, and have a high safety factor and no splashing risk.

High-efficiency charging and replenishing materials also work well on converters, which are different from general charging and replenishing materials. Its main features are high material adhesion rate, fast sintering speed, long service life (currently the average service life is about 40 furnaces), etc., which provides effective protection for converter protection. The new charging and replenishing machine has been put into use, which has greatly improved the accuracy and efficiency of the projectile, reduced the labor intensity of the workers in front of the furnace, and achieved good results. The introduction of converter anti-slag coating is used for spraying at the converter mouth and other slag-sticking areas, which effectively improves the slag cleaning efficiency and reduces the intensity of on-site operations.

Since the introduction of environmentally friendly water-based large-surface materials, the maintenance capacity, maintenance effect and safety of the converter body have been improved, the production capacity has been effectively released, the maintenance cost and pollution of the converter have been reduced, and efficient, green and low-cost production has been achieved.

The average sintering time of the new environmentally friendly large-surface material is 25 minutes, which is 35 minutes shorter than the traditional type. The average service life of the new environmentally friendly large-surface material is 83 furnaces, which is 58 furnaces longer than the traditional type.

Through the comparison of benefits, it is not difficult to see the advantages of environmentally friendly large-surface self-flowing materials in increasing production and efficiency:

First, the maintenance time of the converter body is 35 minutes less than the original refilling time/each time, and the annual steel output of 8 converters can be increased by 16,800 tons. The benefit per ton of steel is calculated at 500 yuan, and the annual benefit reaches 8.48 million yuan.

Second, due to the increase in the number of corrosion-resistant furnaces of water-based large-surface materials, the number of refilling times has been reduced, and the consumption of refilling materials has been reduced from the original 0.368 kg/ton of steel to the current 0.195 kg/ton of steel, the consumption of furnace protection materials has been reduced by about 1,450 tons, and the maintenance cost of the furnace body has been reduced by about 200,000 yuan/year.

The application of environmentally friendly carbon-free water-based lining materials in the converter of Shaoguan Iron and Steel Co., Ltd. shows that the average sintering time of the new environmentally friendly lining materials is 25 minutes, which is 35 minutes shorter than that of the traditional type; the average service life is 41 furnaces, which is 29 furnaces longer than that of the traditional type. A single converter can produce about 880 more furnaces of steel in one furnace, increase steel production by about 115,000 tons, and reduce lining material consumption by more than 700 tons.