After shoveling the material flat with a shovel, step on it with your foot to remove the air, insert the steel drill into the material and shake it repeatedly, and then use your foot to further solidify. The thickness of each layer of the dry ramming material should be 150~200mm. , And then use a knotting tool to repeatedly beat it 3 times in a spiral shape from the periphery to the center.

The method to check the quality of knotting is usually to put a round steel with a diameter of 5mm on the ramming layer and press it down with a pressure of 10kg, and its depth does not exceed 30mm. Steel drills can be inserted forcefully during on-site construction, and the depth should not exceed 30mm. The method of knotting the furnace slope is the same as that of the furnace bottom. First, use your feet firmly, and then use the knotting device to ramming. The maximum angle between the furnace slope and the furnace bottom does not exceed 40°. Prevent rolling or collapse due to the furnace slope is too large.

In places where steel tapping fire bricks, furnace doors and other places where molten steel is agitated and scoured severely, it should be beaten vigorously and the size should be appropriately thickened to extend the service life of the refractory materials in these damaged parts as much as possible.

After the ramming is finished, cover the 5~10mm thick steel plate on the ramming material to prevent the shape of the furnace bottom from being damaged or the waste steel penetrates the ramming material layer when loading the scrap steel, which will cause the hidden danger of steel leakage. If steel cannot be made in time, 100~200mm thick lime should be placed on the iron plate to prevent hydration of the ramming material.

When knotting the ramming material, it must be operated strictly in accordance with the construction requirements to ensure the compactness of the ramming material, otherwise it will cause the ramming material to shrink seriously during use, causing a large number of cracks and spalling, resulting in a decrease in life. The first furnace is very important for smelting, and the oxygen blowing pipe must not be inserted too deep during oxygen blowing and decarburization, otherwise it is easy to cause the ramming material at the bottom of the furnace to turn up and produce big pits. During the smelting of the first furnace, the bottom of the furnace can be covered with a layer of lime, which not only prevents the scrap steel from directly hitting the bottom of the furnace, but also prevents the ramming material from hydrating, and can form slag earlier.

More details about Ramming Mass

What is a ramming mass?

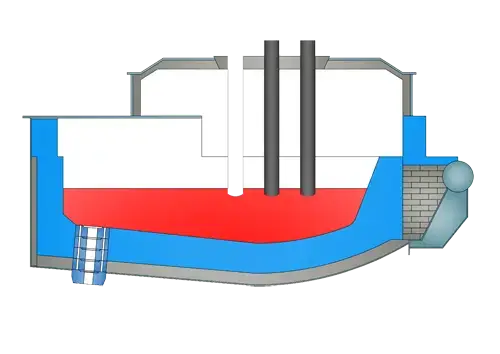

Ramming mass is a pre-blended Dry vibratables refractory made from a selected mix of SILICA GRAINS. This blend of grains along with a binder, BORIC ACID forms the working lining in an Induction furnace used for melting steel.

What is ramming in foundry refractory mass?

Ramming mass is an unshaped refractory material that is used to line the bottom/bank of the Furnace to prevent corrosion, erosion & thermal shock. Basic ramming mass is mainly composed of Magnesia (MgO), which has high refractoriness, slag resistance & thermal stability.

What is the bulk density of ramming mass?

Product Name: Refractory Ramming Mass. Bulk Density: 1.7-2.2g/cm3. Cold Crushing Strength: ≥50MPa. Shape: Granular, Powder.